Guide to Receiving Finished Goods from External Suppliers

Learn the complete process of receiving finished goods from suppliers, including status changes, quality checks, and system messages.

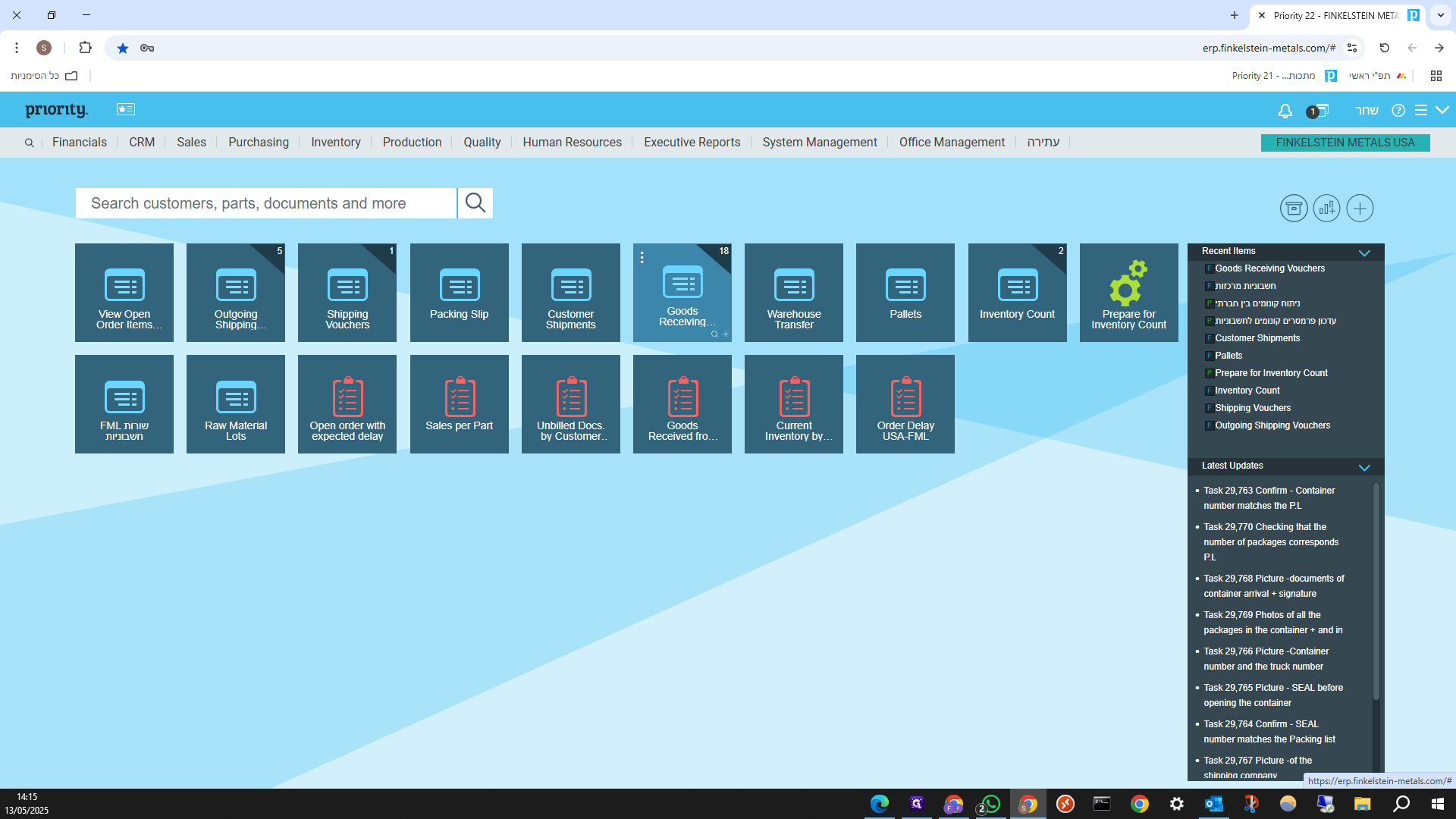

In this guide, we'll learn how to manage the process of receiving finished goods from external suppliers. We'll explore the necessary status changes throughout the process, how to conduct quality checks, and the new warning or stop messages in the system. We'll begin by accessing the "Receiving Goods from Suppliers" screen and using a receipt from Sabak Metals as an example. The guide will also cover how to handle errors and ensure compliance with quality assurance protocols using the Priority application.

Let's get started

Hello everyone. In this guide, we will cover and present the entire process of receiving finished goods from external suppliers. What statuses do we need to change throughout the process? How do we conduct quality checks? What new warning or stop messages do we have in the system, and which messages will be sent to the relevant departments?

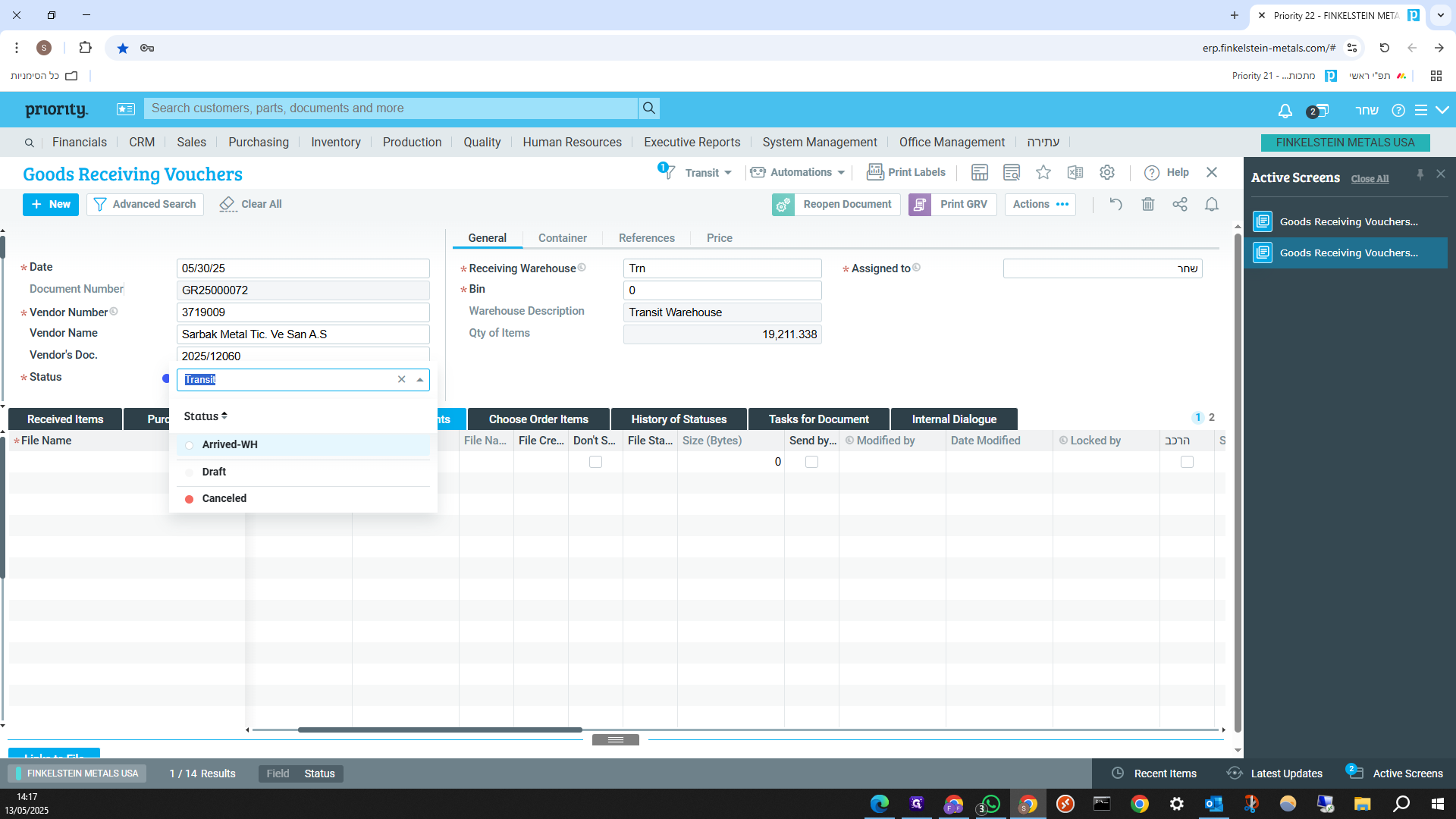

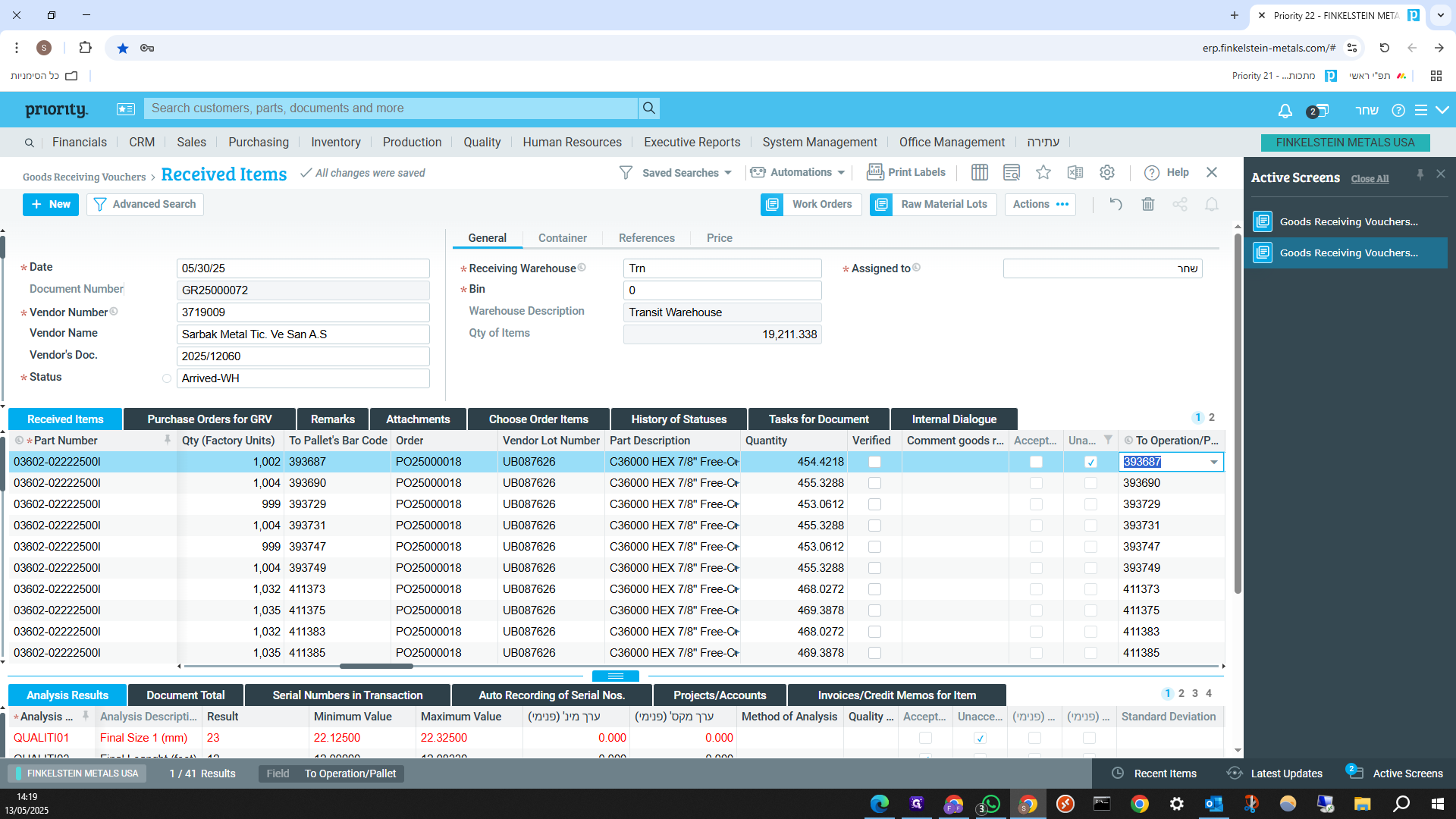

We will start by entering the "Receive Goods from Suppliers" screen. For this example, we are looking at a receipt from Sabak Metals and will go over all the details.

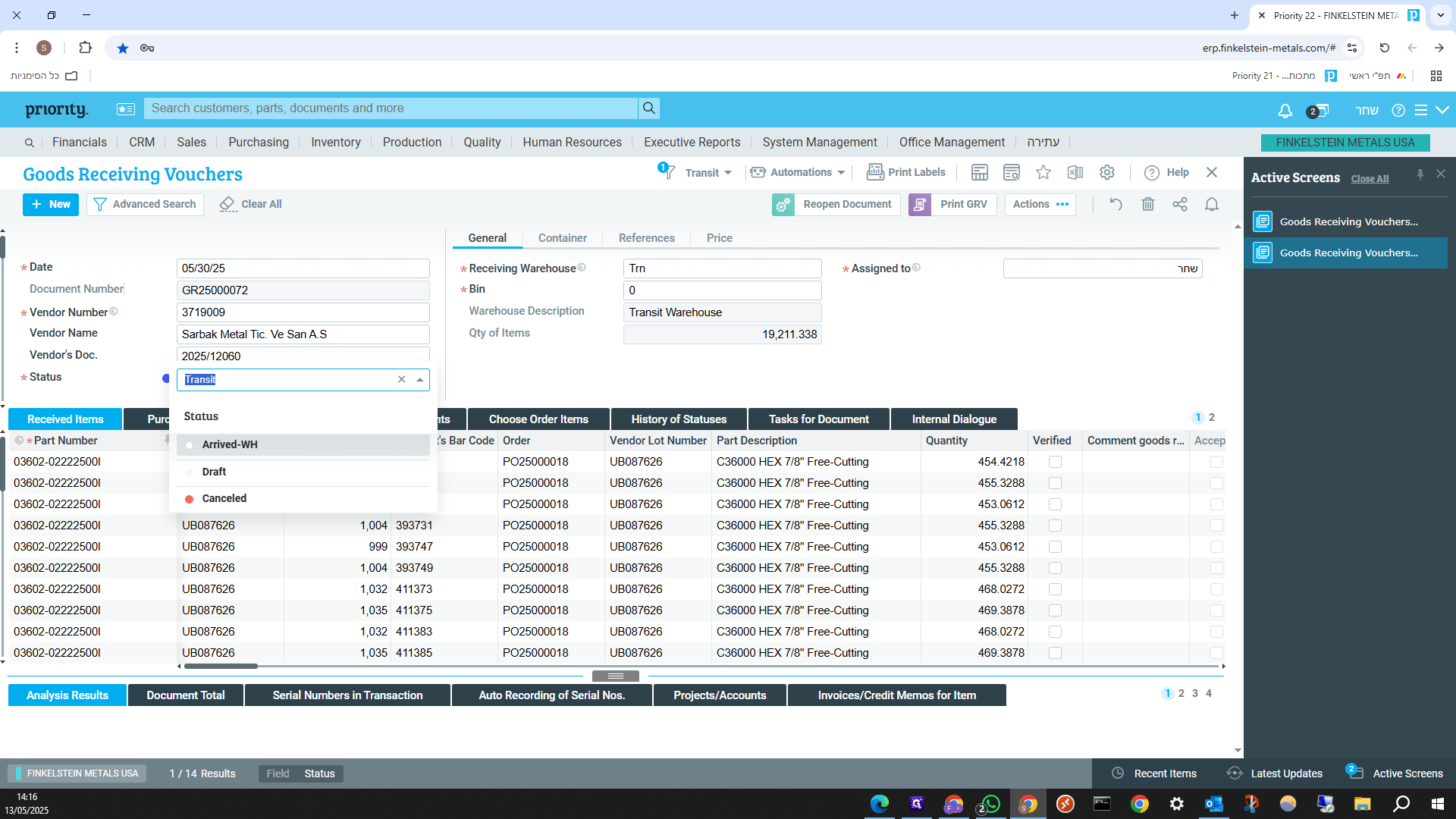

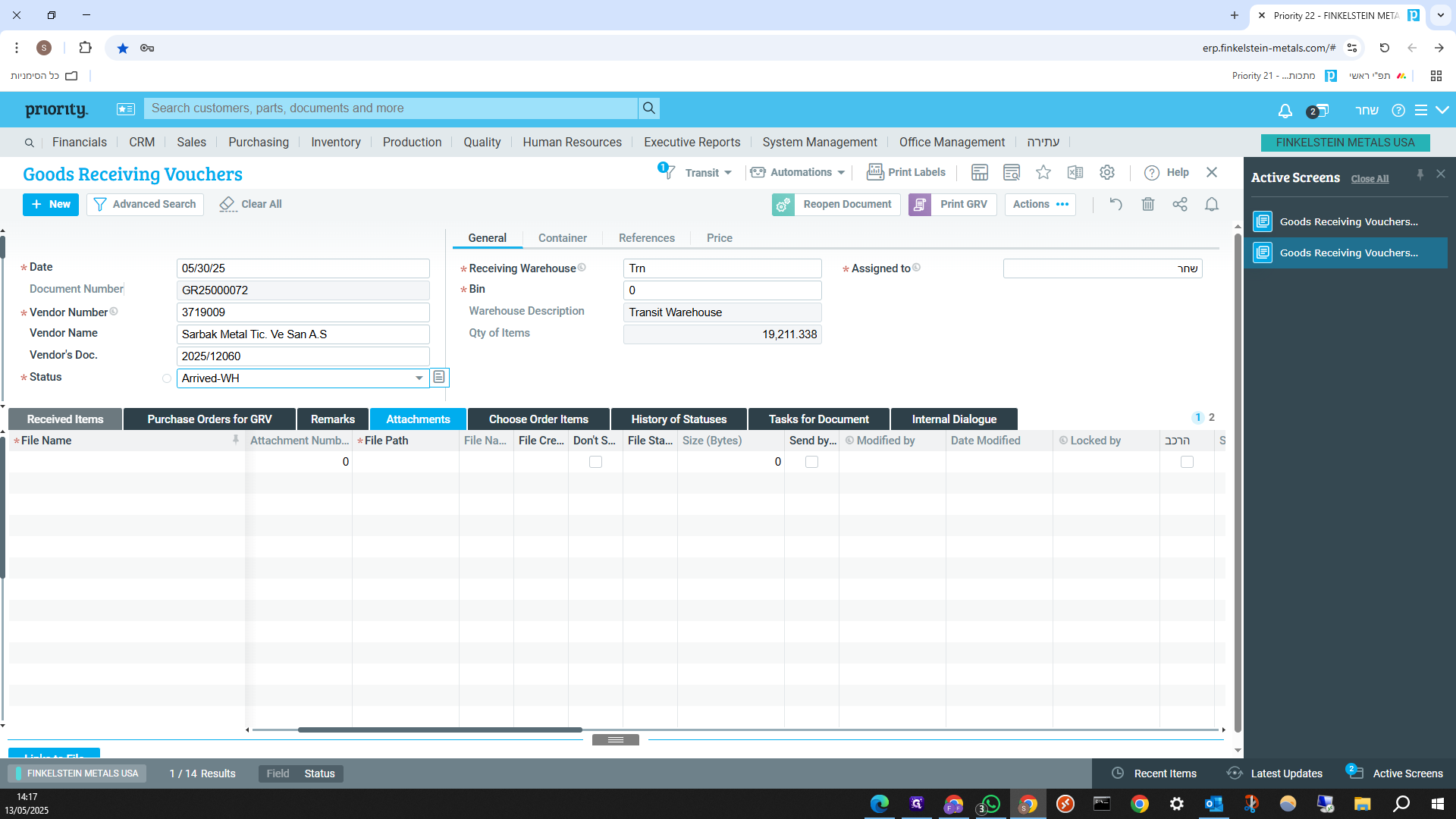

When we enter the certificate, and the container arrives, we must change the certificate status from "transit" to "arrived WH." Click on the status and move to Archived WH.

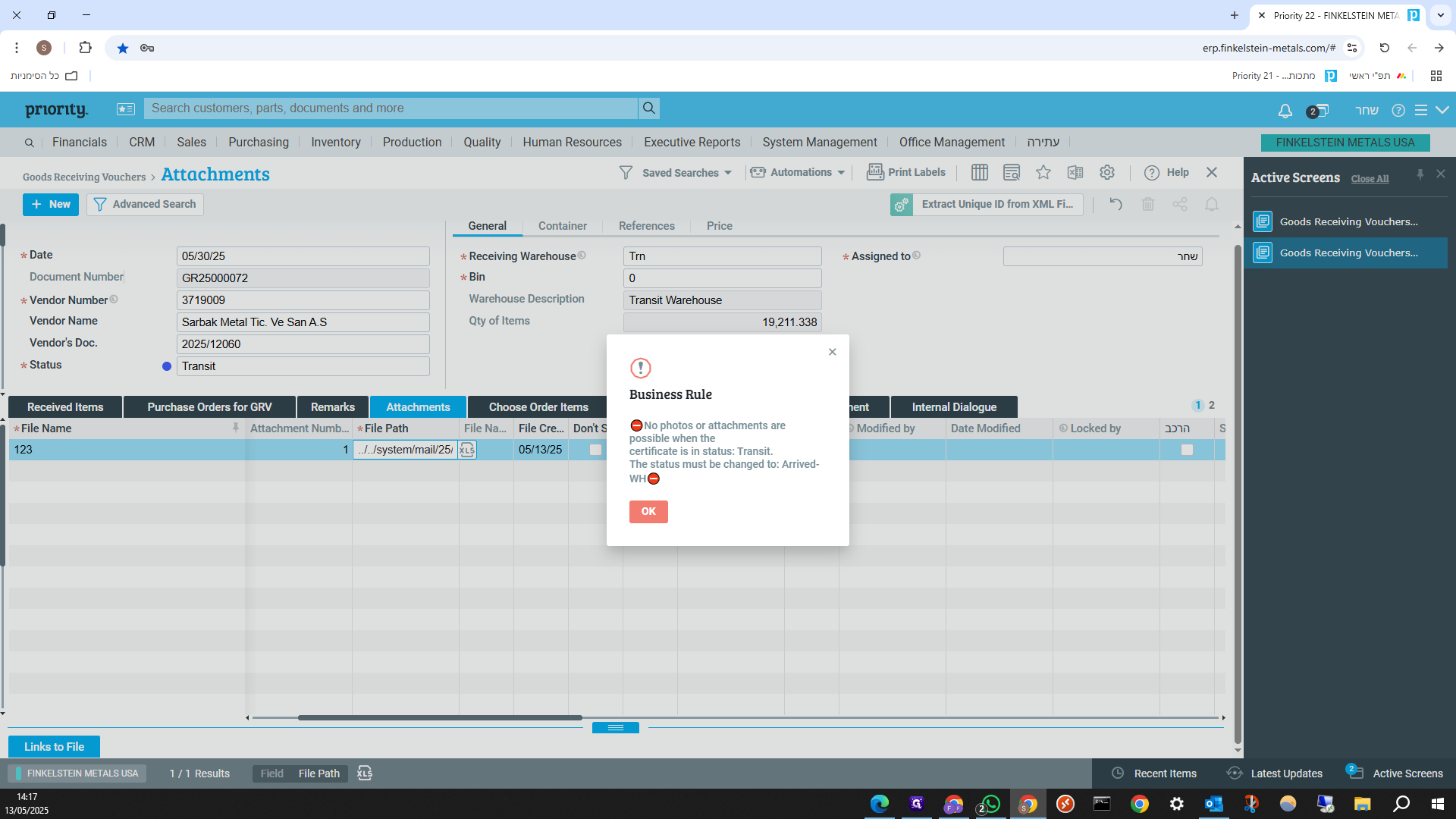

If we do not make this change and try to add images during the goods receipt stage, we will receive a warning message.

Note which warning message will appear if the status is not changed to Archived WH.

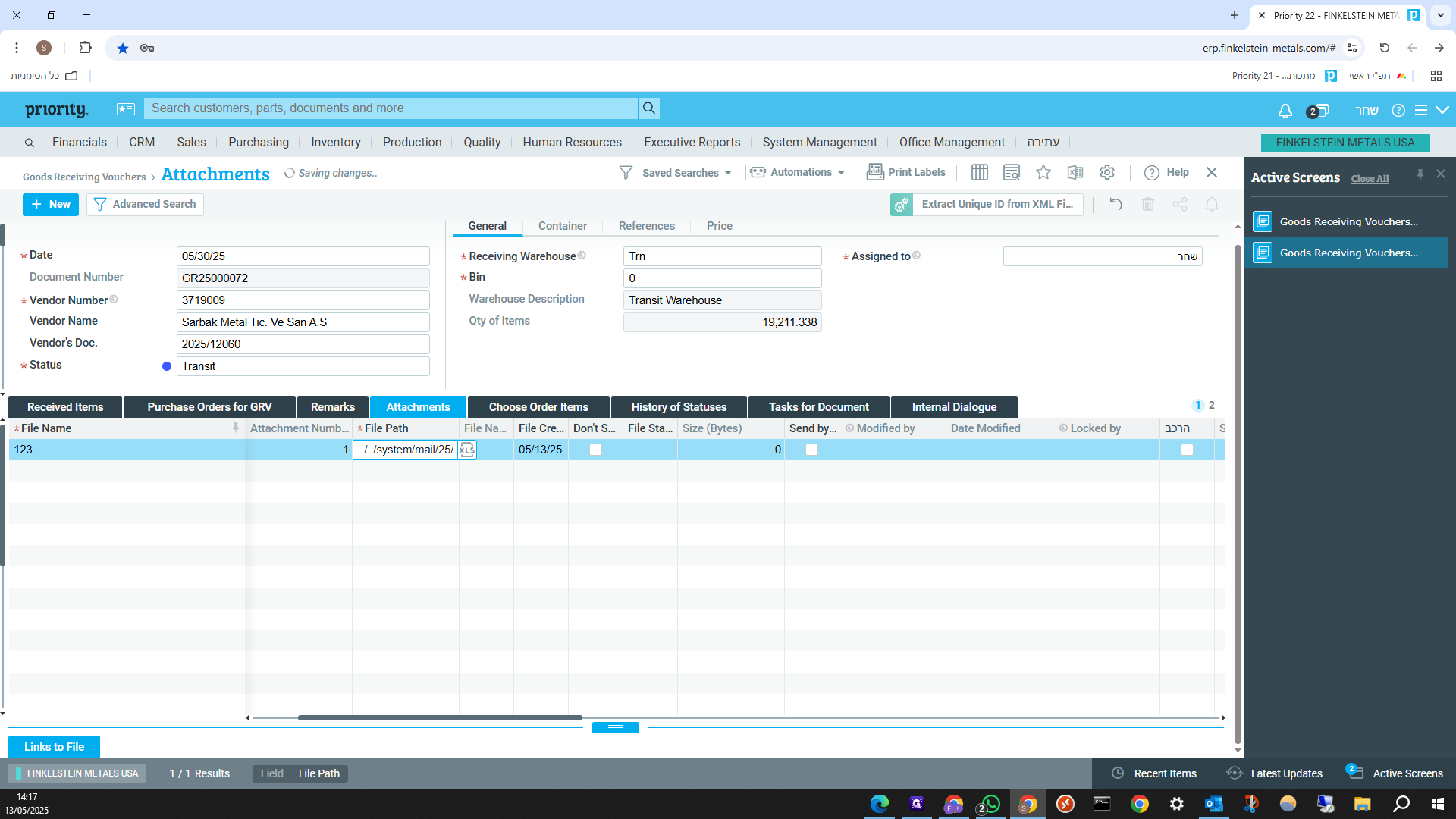

After changing the status to "Archived WH" and uploading the images, we will proceed to the quality checks stage.

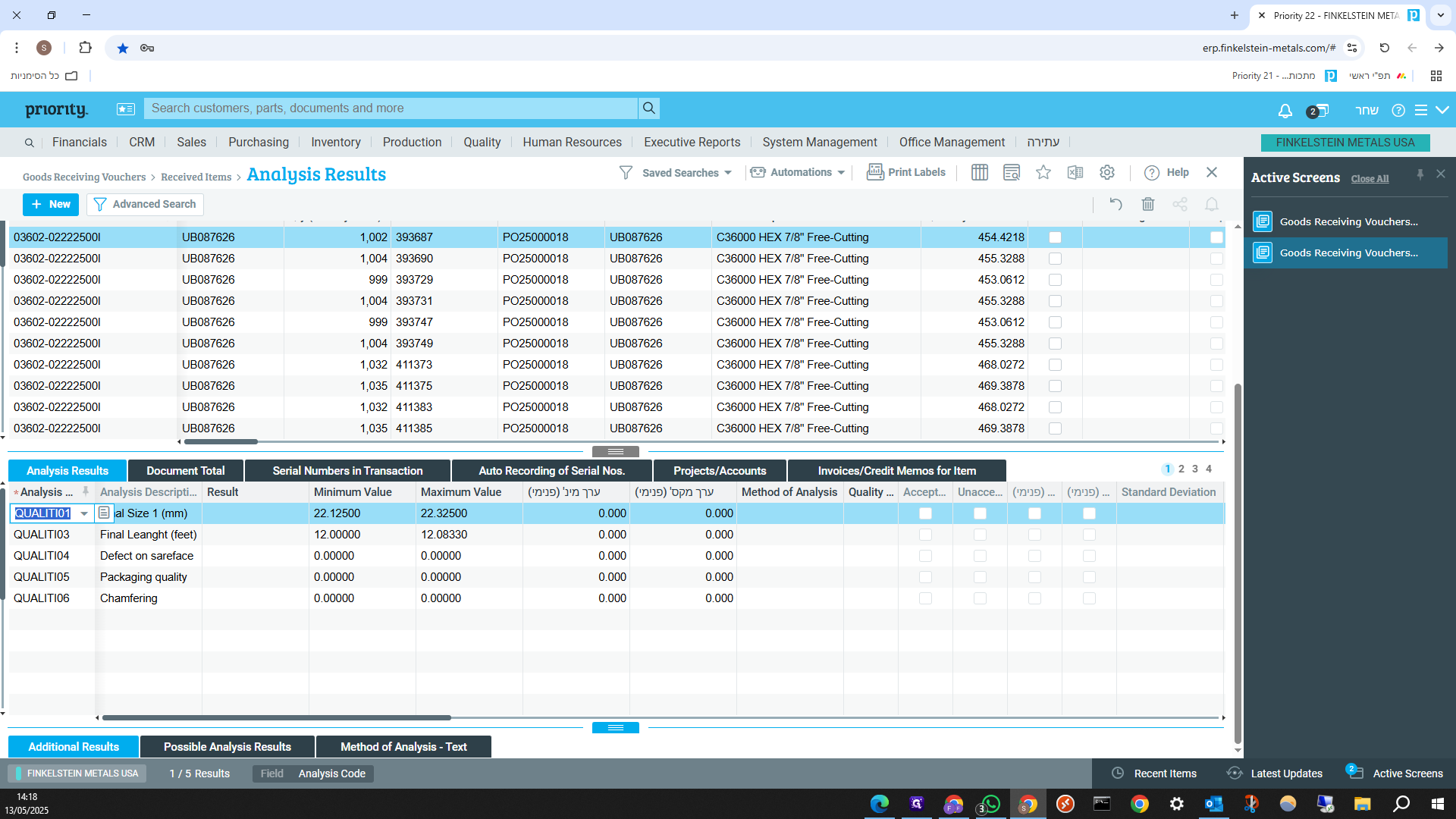

Of course, we actually do this using the Priority app, and I will now demonstrate it on the computer. We are going to the quality inspection screen for the package after scanning the package's pallet number.

We go to the result and enter the obtained outcome.

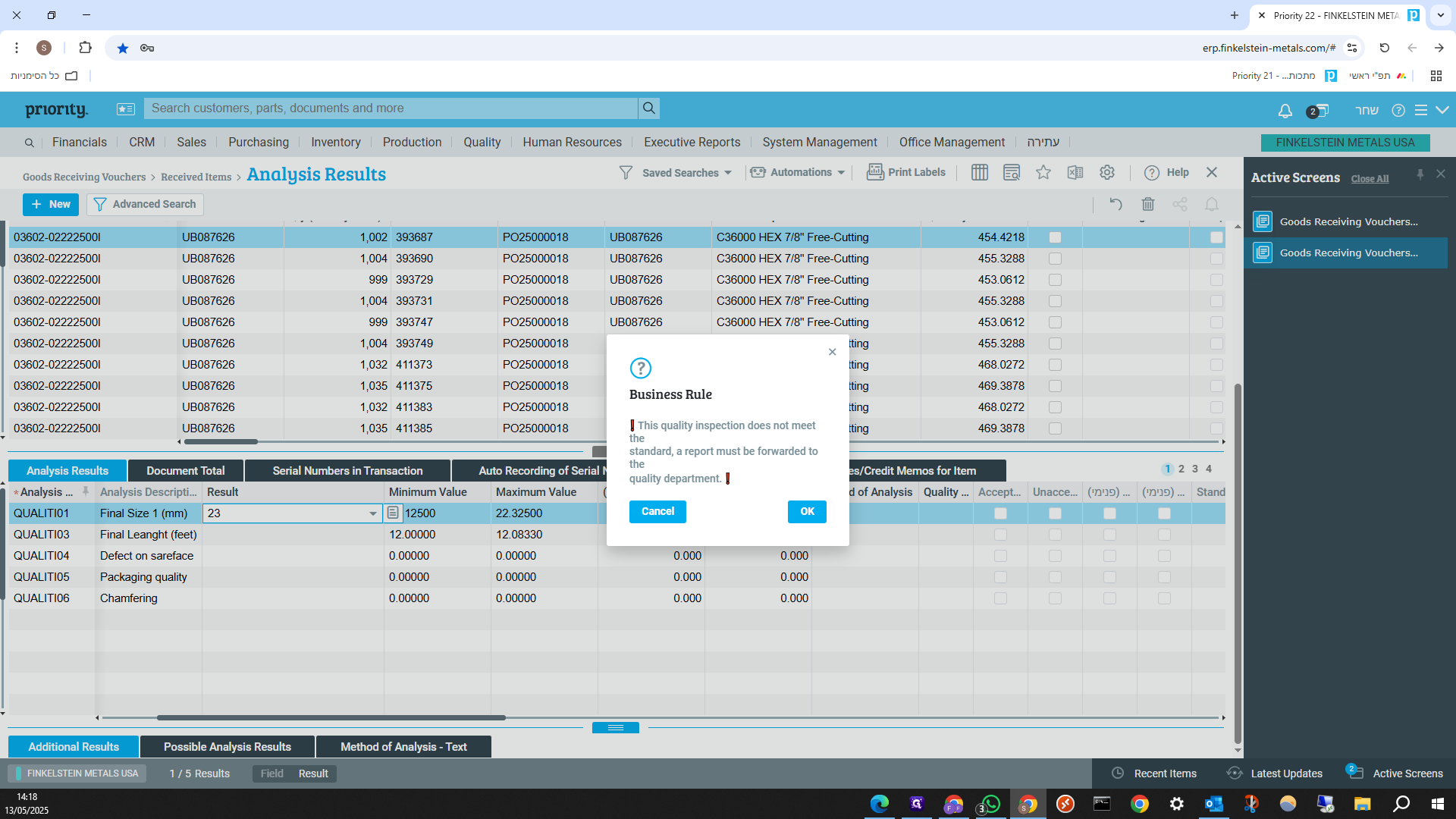

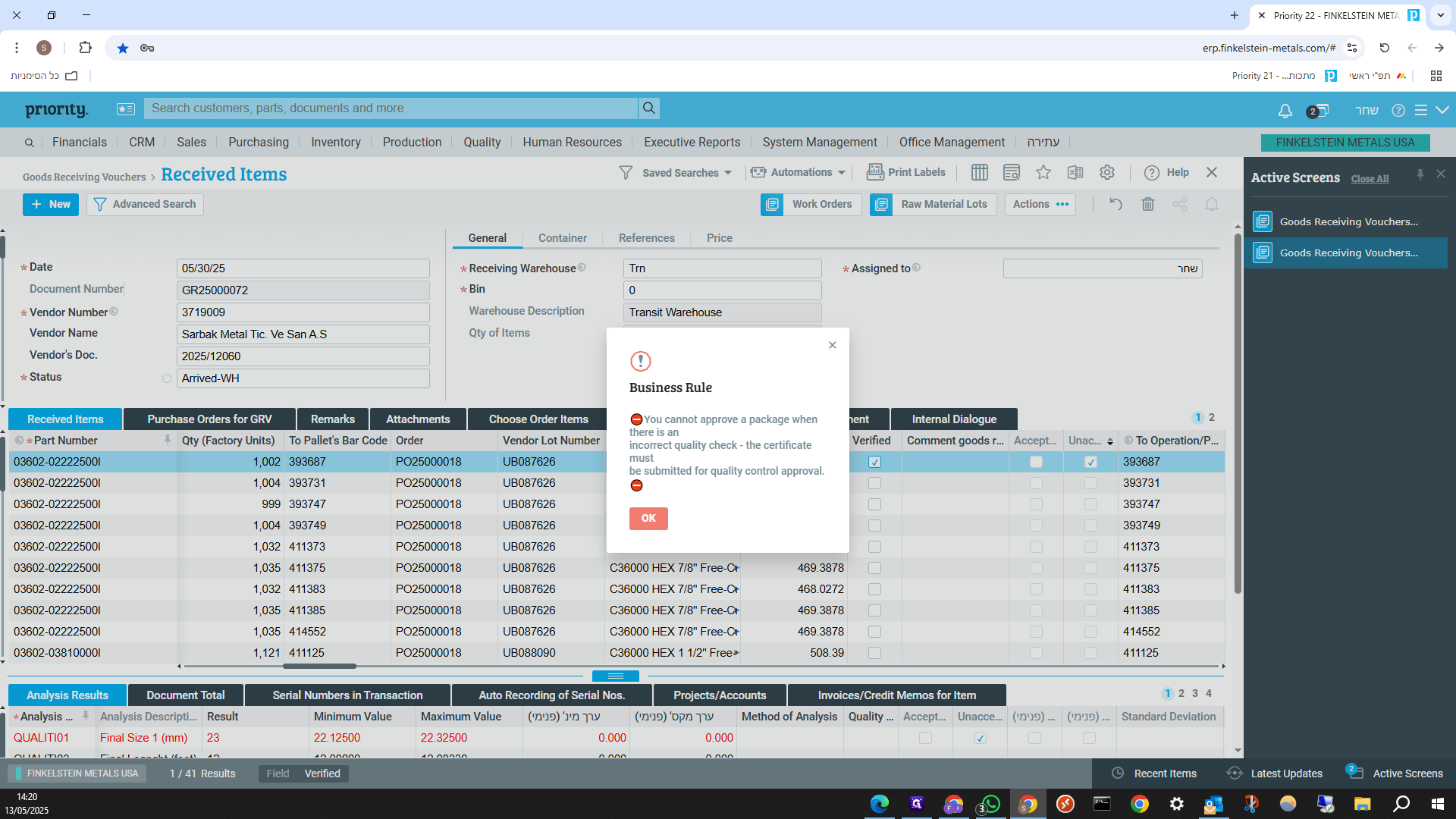

If the result is incorrect and does not meet the tolerance, we will receive the following error message. We can click "OK" and move on to the next check.

After completing all the tests, ensure that all equipment is turned off. Then, proceed to clean the workspace thoroughly. Make sure to store all tools and materials in their designated places. Finally, review the checklist to confirm that all tasks have been completed. We returned to the package screen.

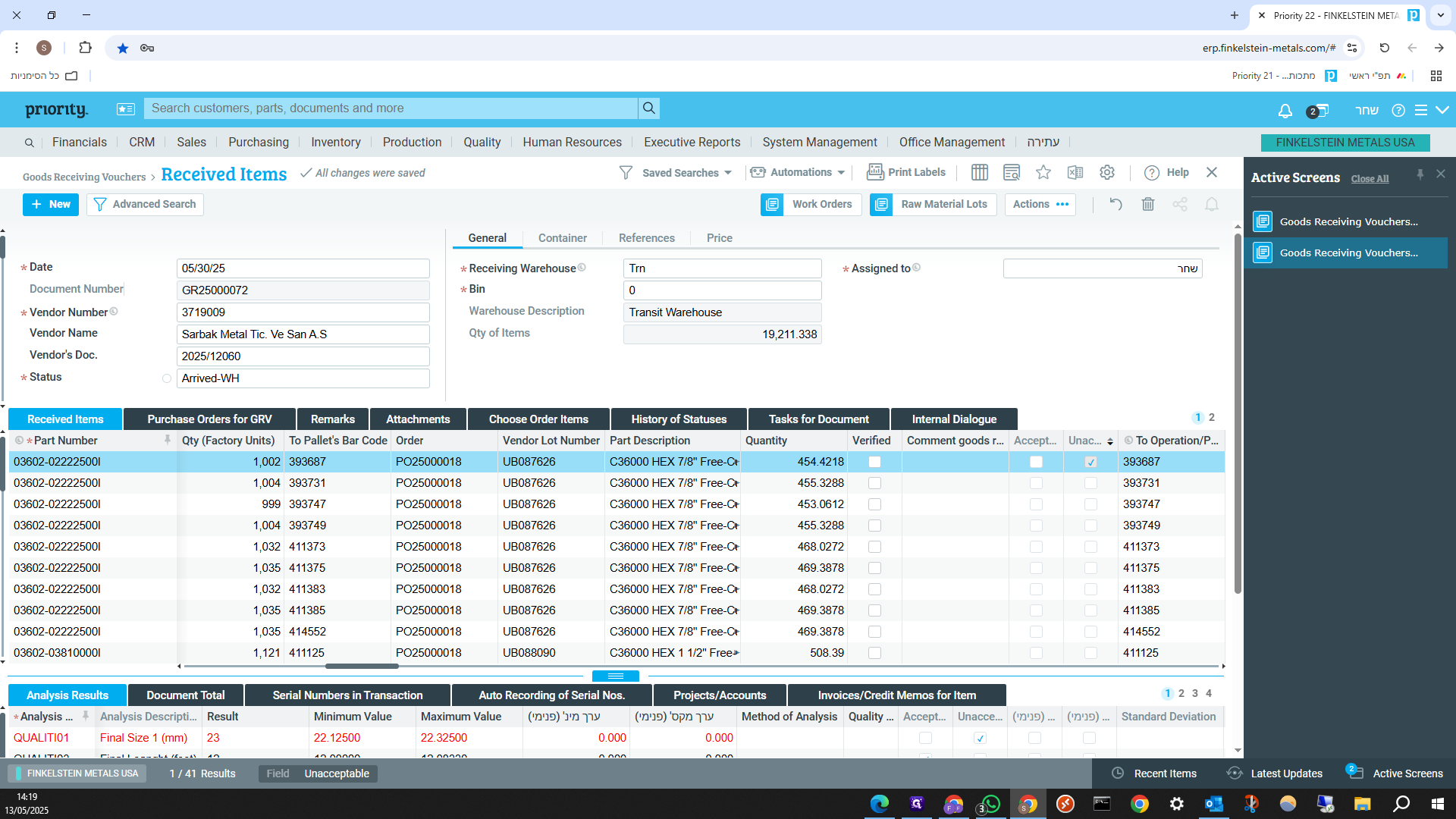

If the package is not approved and you try to click on "Verified" and move to the next line.

The certificate must be sent to the Quality Assurance Department for approval. Another error message you might receive is if you try to approve a package without completing all the required quality checks. You will get an error message indicating that all quality checks must be completed before approving the package.

If one of the packages in the certificate was not valid...

You can change the certificate status to "Archived QC, Quality Control" for approval by the Quality Assurance department.

You cannot transfer the certificate to the final.