RRVL<>Shelf Life Validations at GRN, & Expiry Management

© LLAMA LOGISOL PVT LTD 2025. All rights reserved. This document and the WMS software described herein are proprietary products of © LLAMA LOGISOL PVT LTD and are protected by copyright law. No part of this document or software may be reproduced, transmitted, or used in any form or by any means without prior written permission from © LLAMA LOGISOL PVT LTD 2025.

In this guide, we'll learn how to process stock arrival and complete a Goods Receipt Note (GRN) through the web in a warehouse management system. We will cover how the system checks for shortfall in remaining shelf life, customer-defined shelf life, and MRP mismatches, and how these checks affect the quality control (QC) process and put away strategies.

You will see how to handle QC approvals, manage rejected quantities, and ensure that stock is routed to the correct locations based on inspection results.

Let's get started

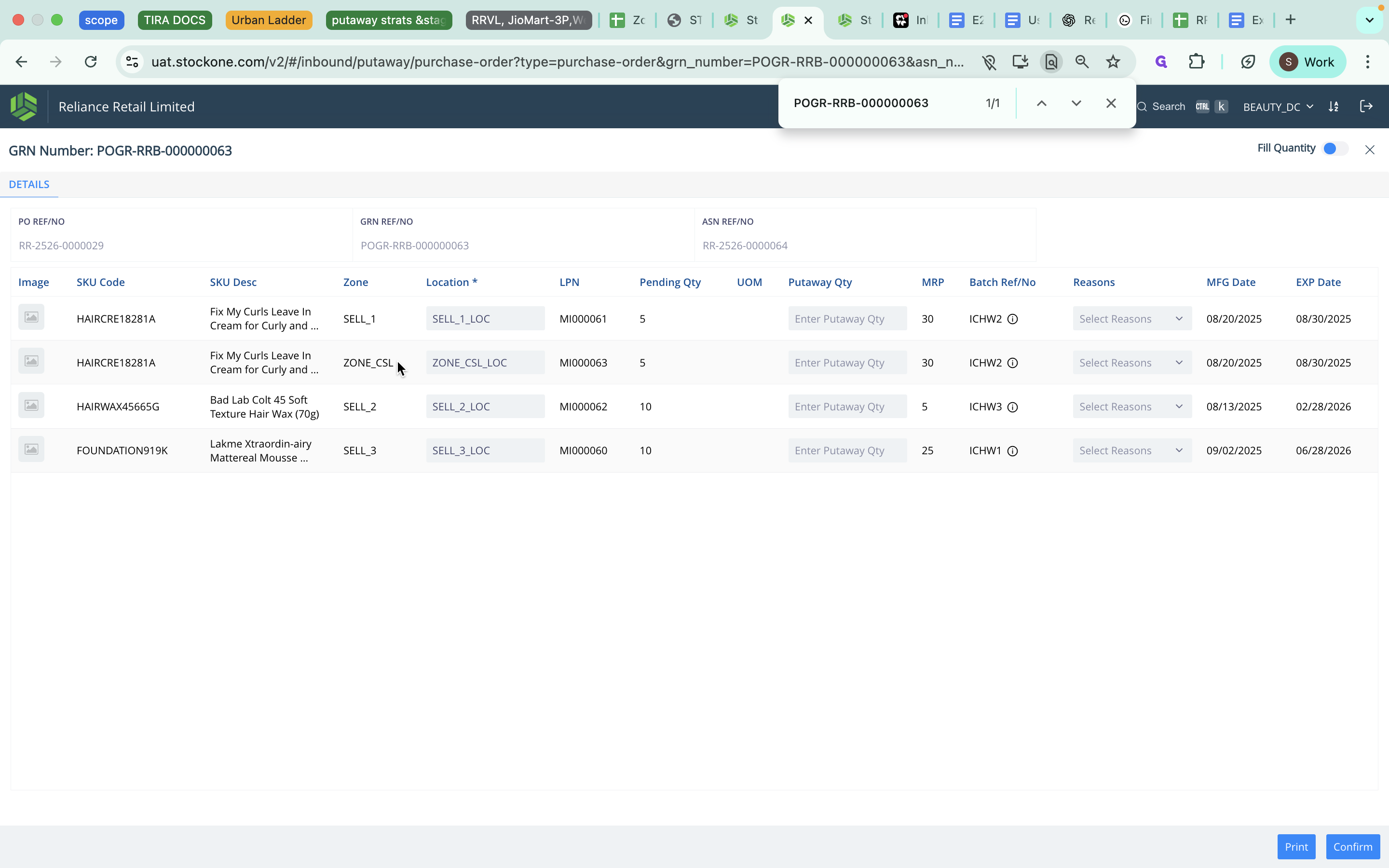

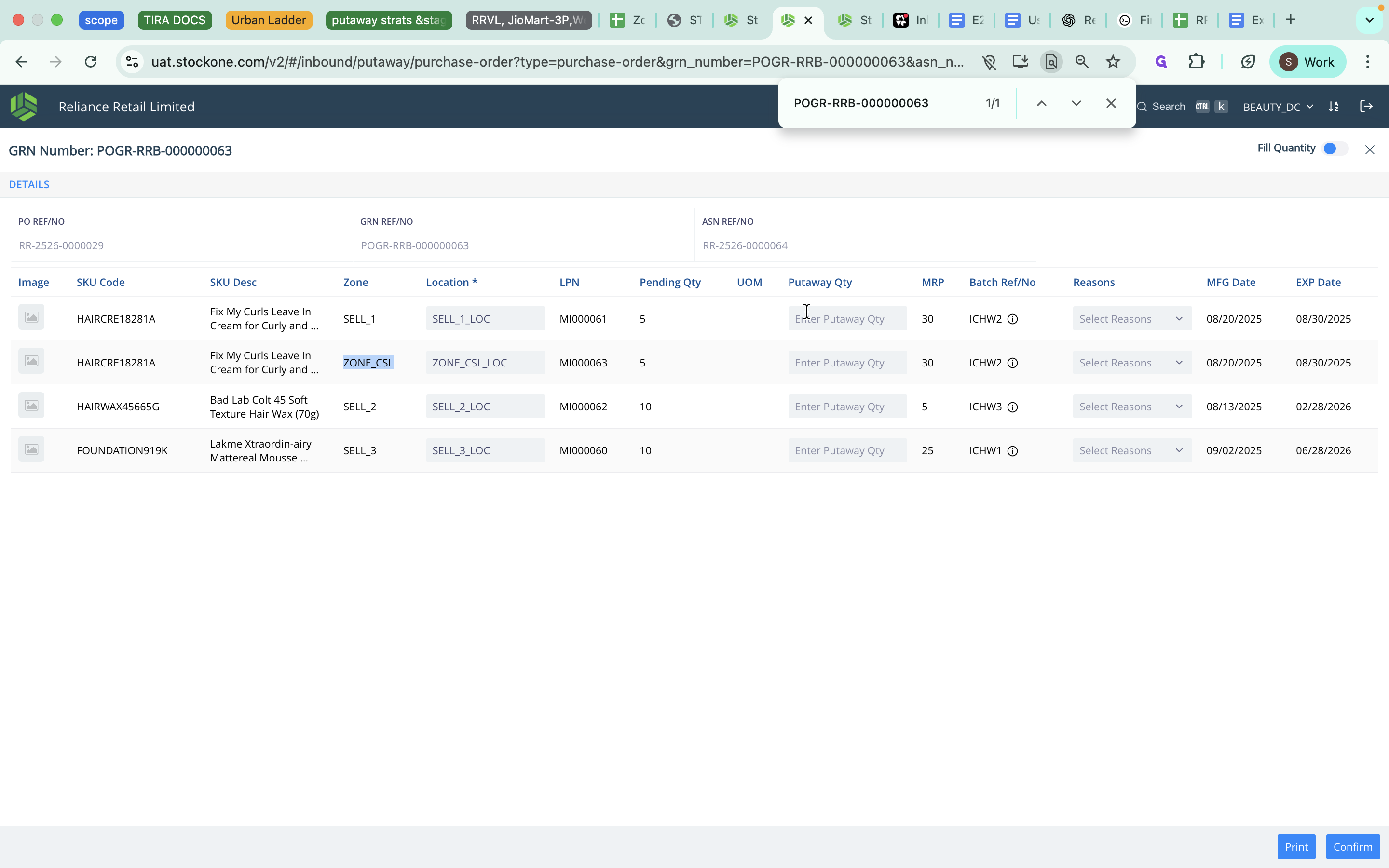

Put-away location recommendations are made based on quality control, rejection reasons, and predefined locations in the put-away strategies.

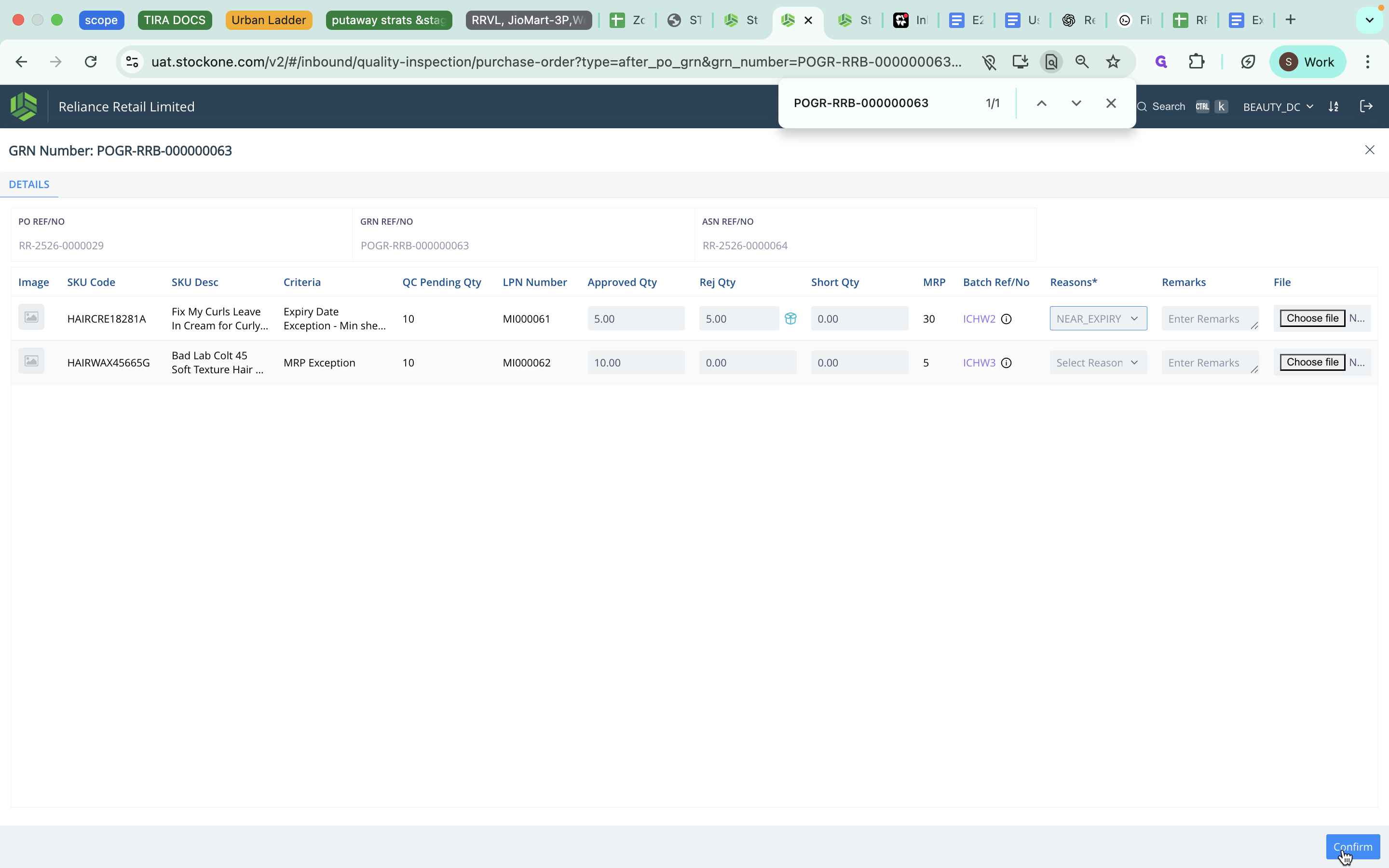

The shelf life check is done against the minimum shelf life and customer shelf life. MRP mismatches are calculated based on the MRPs provided in the ASN. All QC criteria that are breached will be routed through quality control. Based on the QC results, quantities will be either accepted or rejected. Rejection reasons will be provided for any rejected quantities, and the put-away process will proceed accordingly.

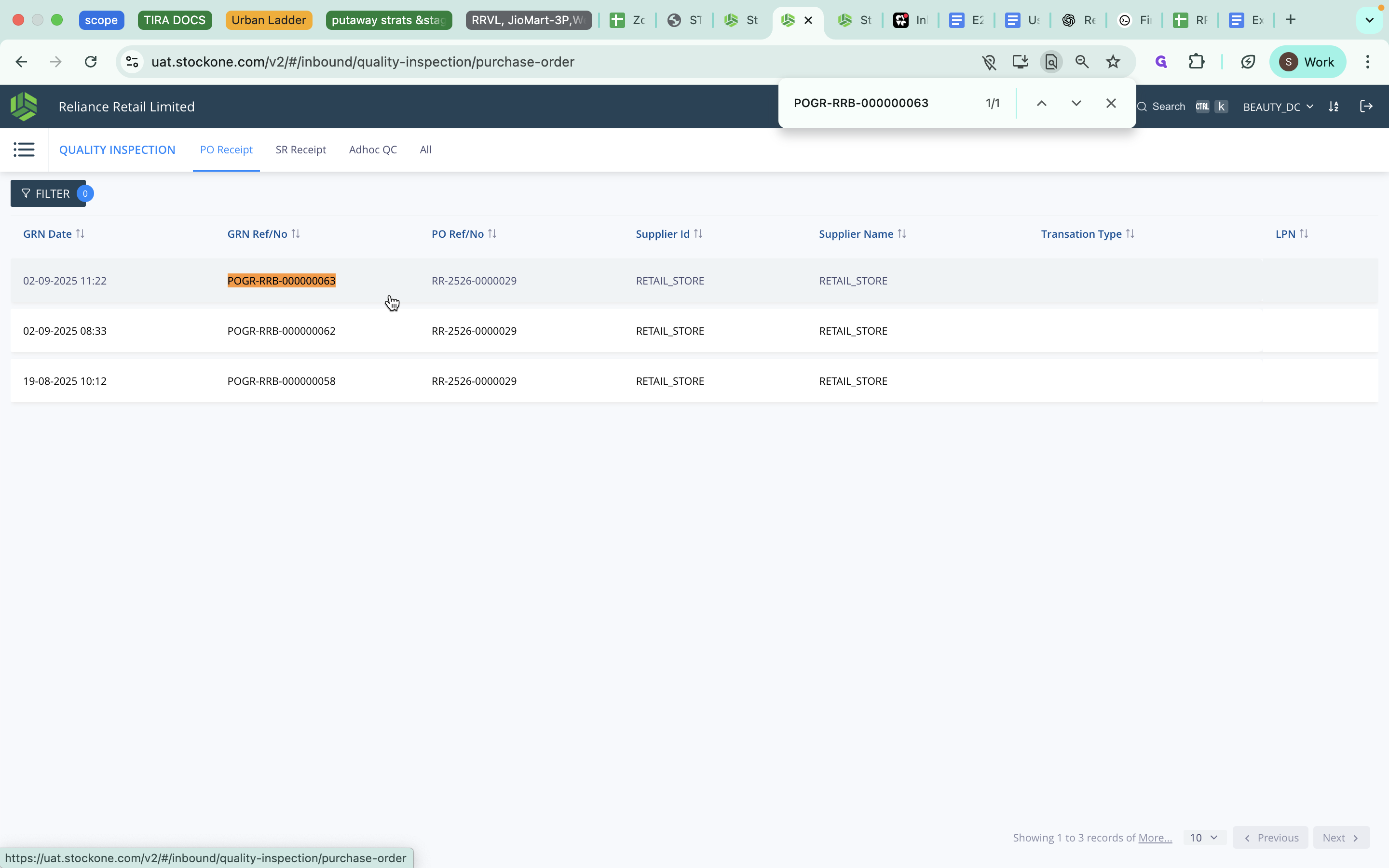

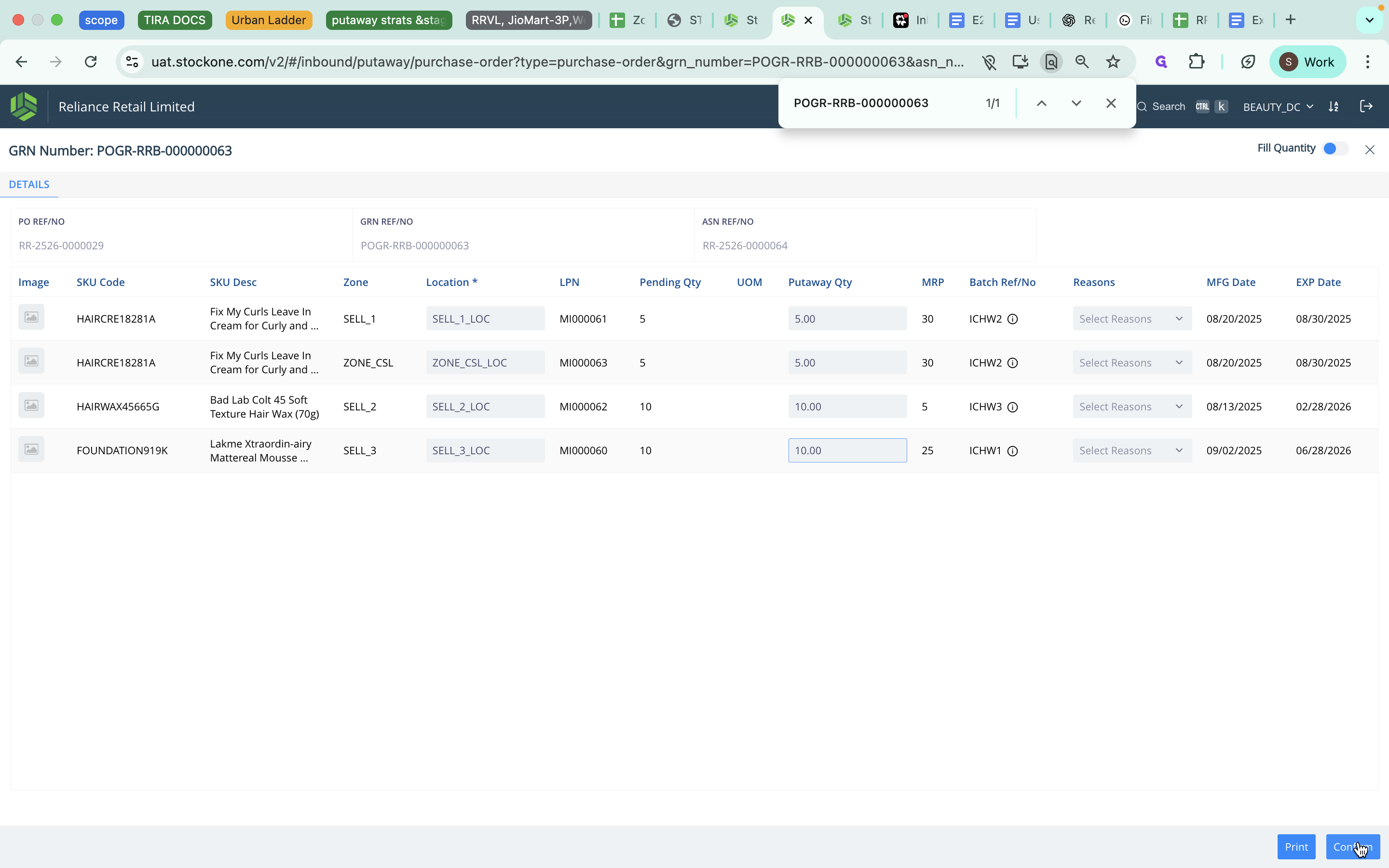

Here, we will process the GRN.

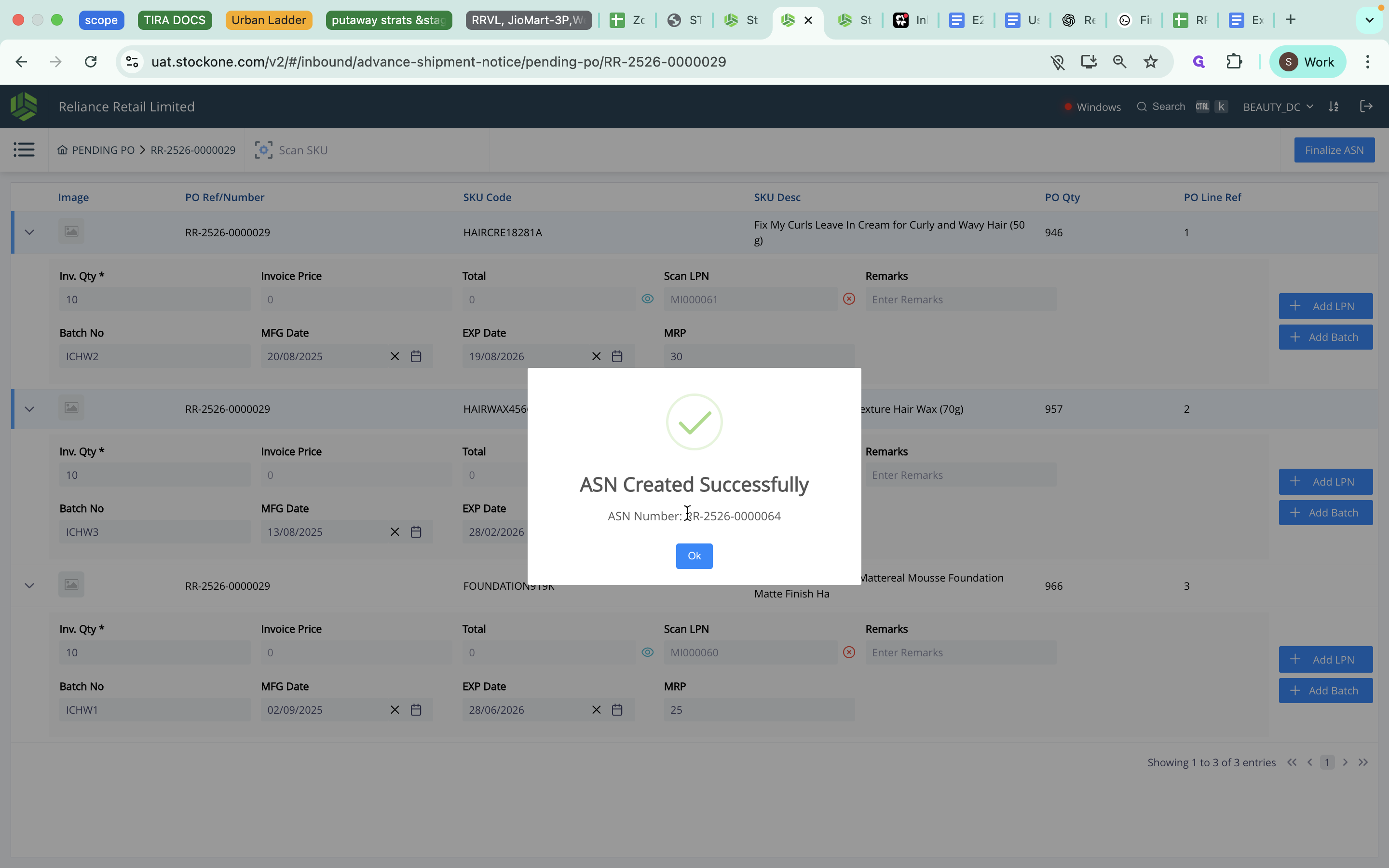

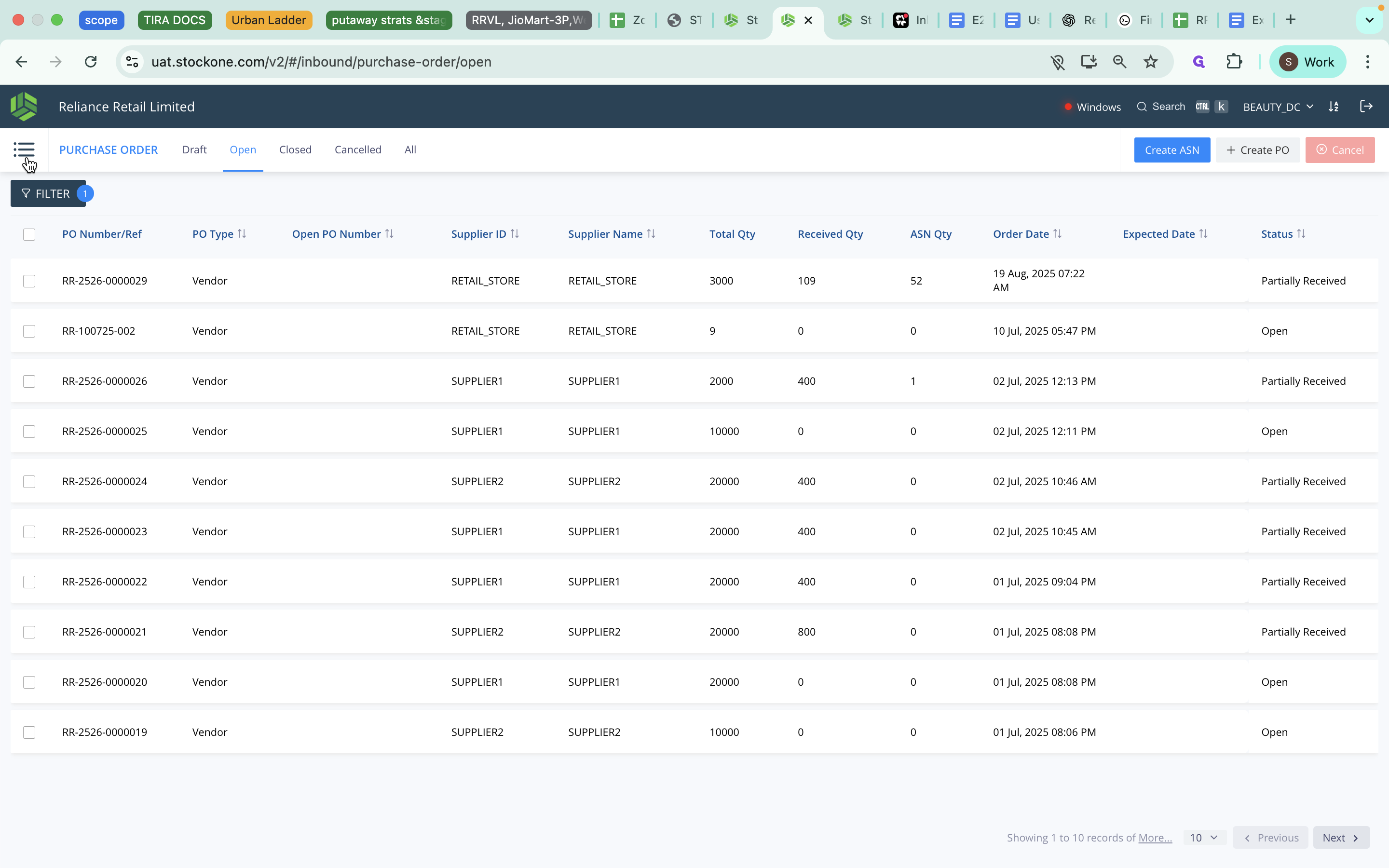

First, we are creating an ASN.

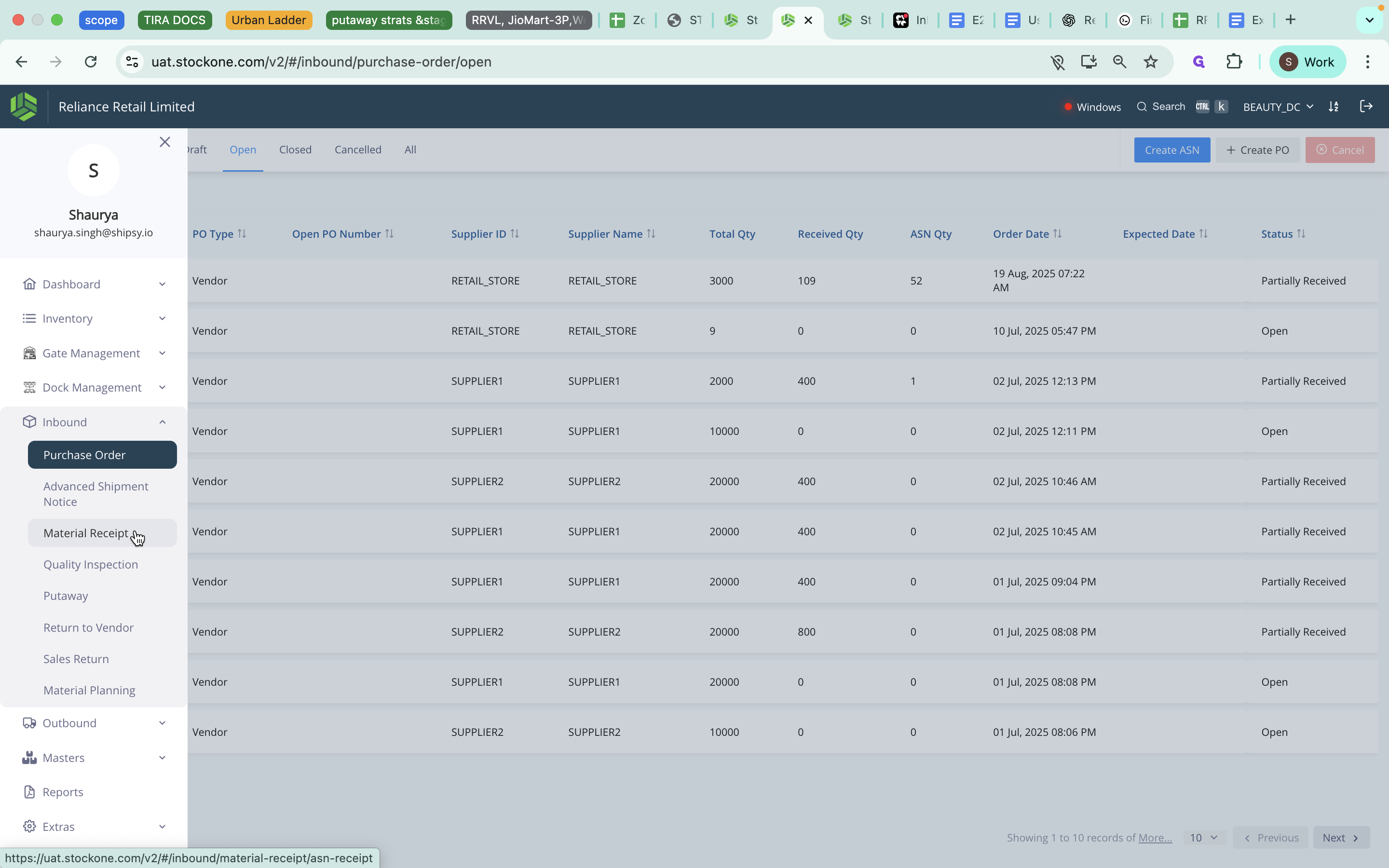

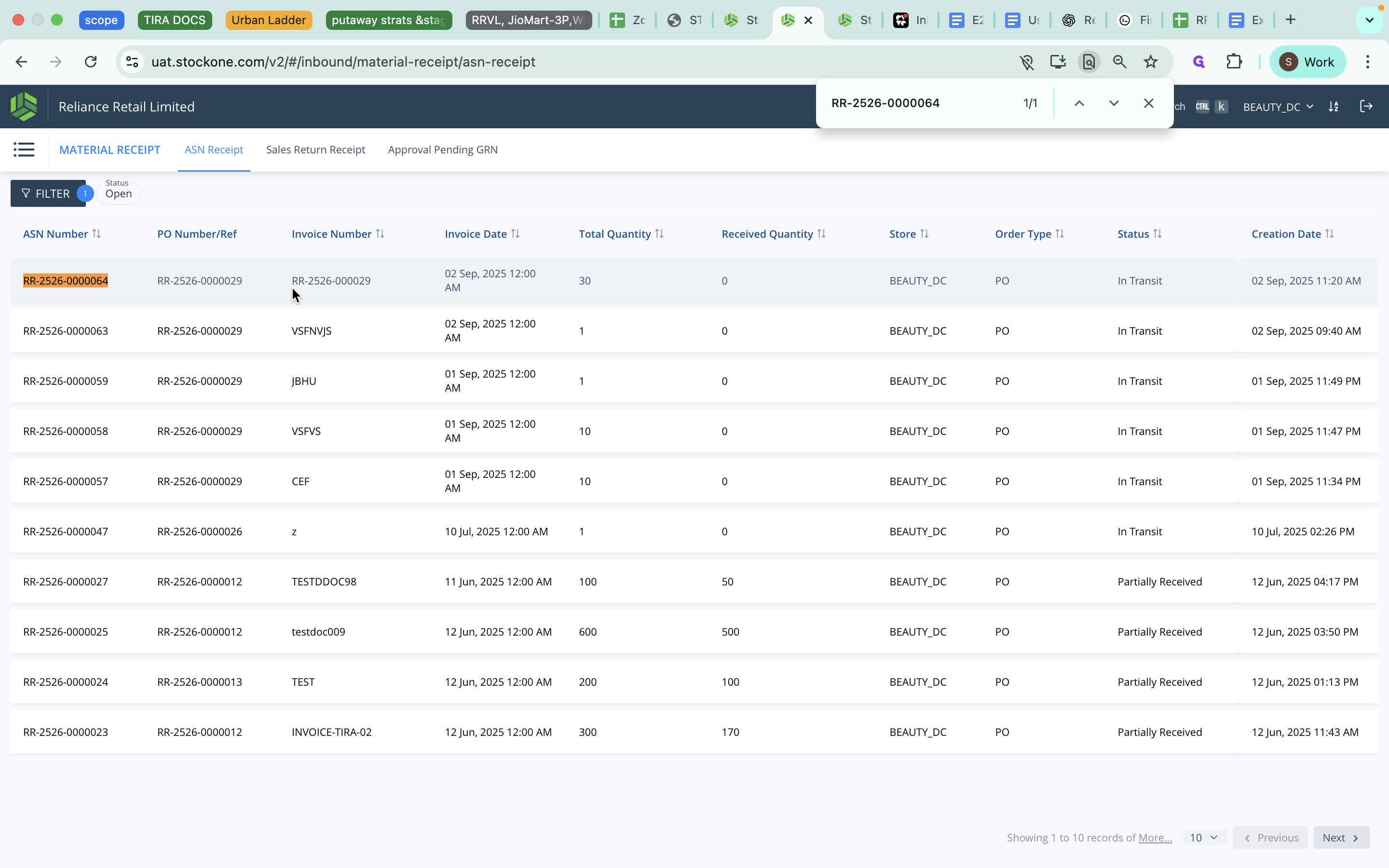

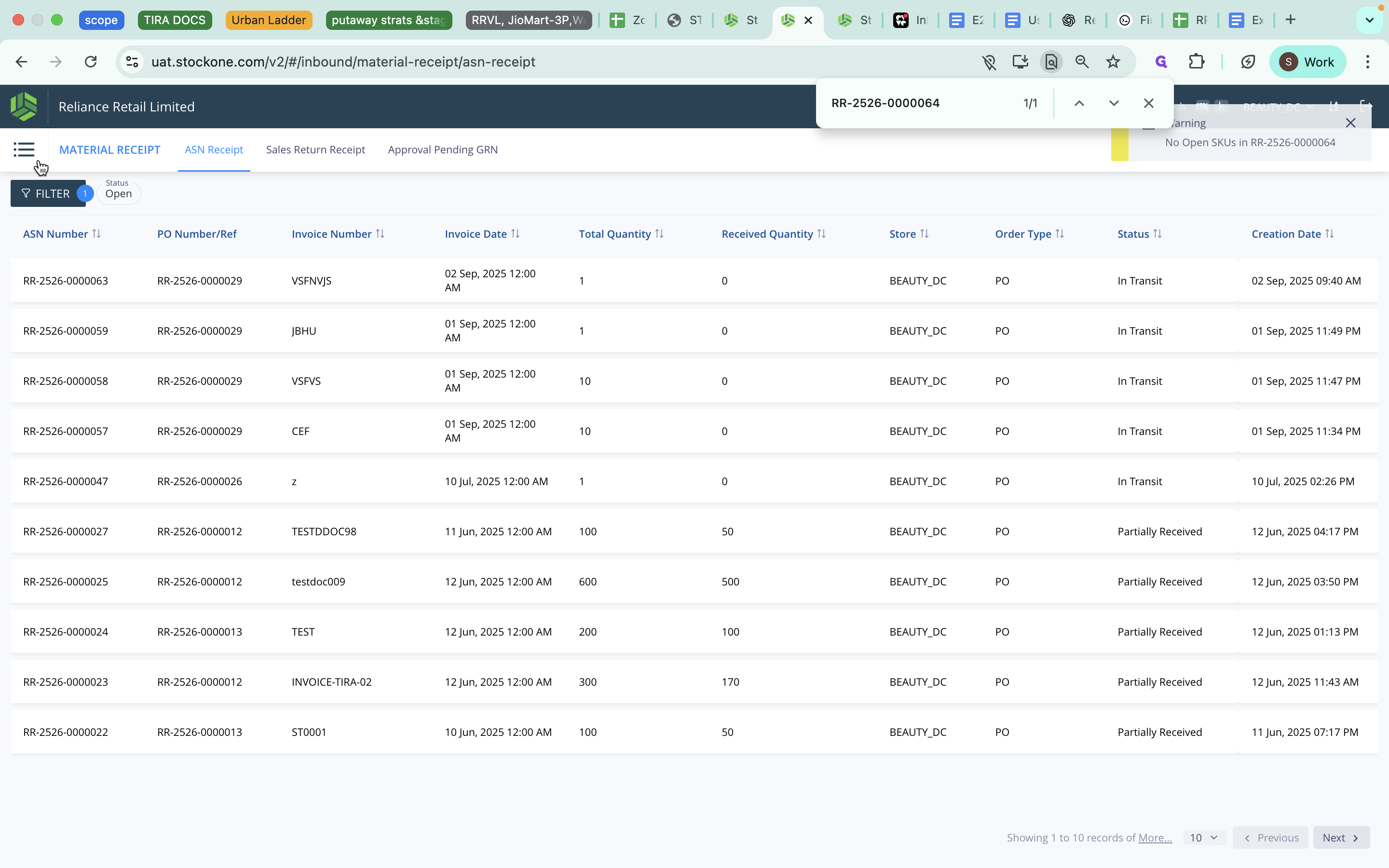

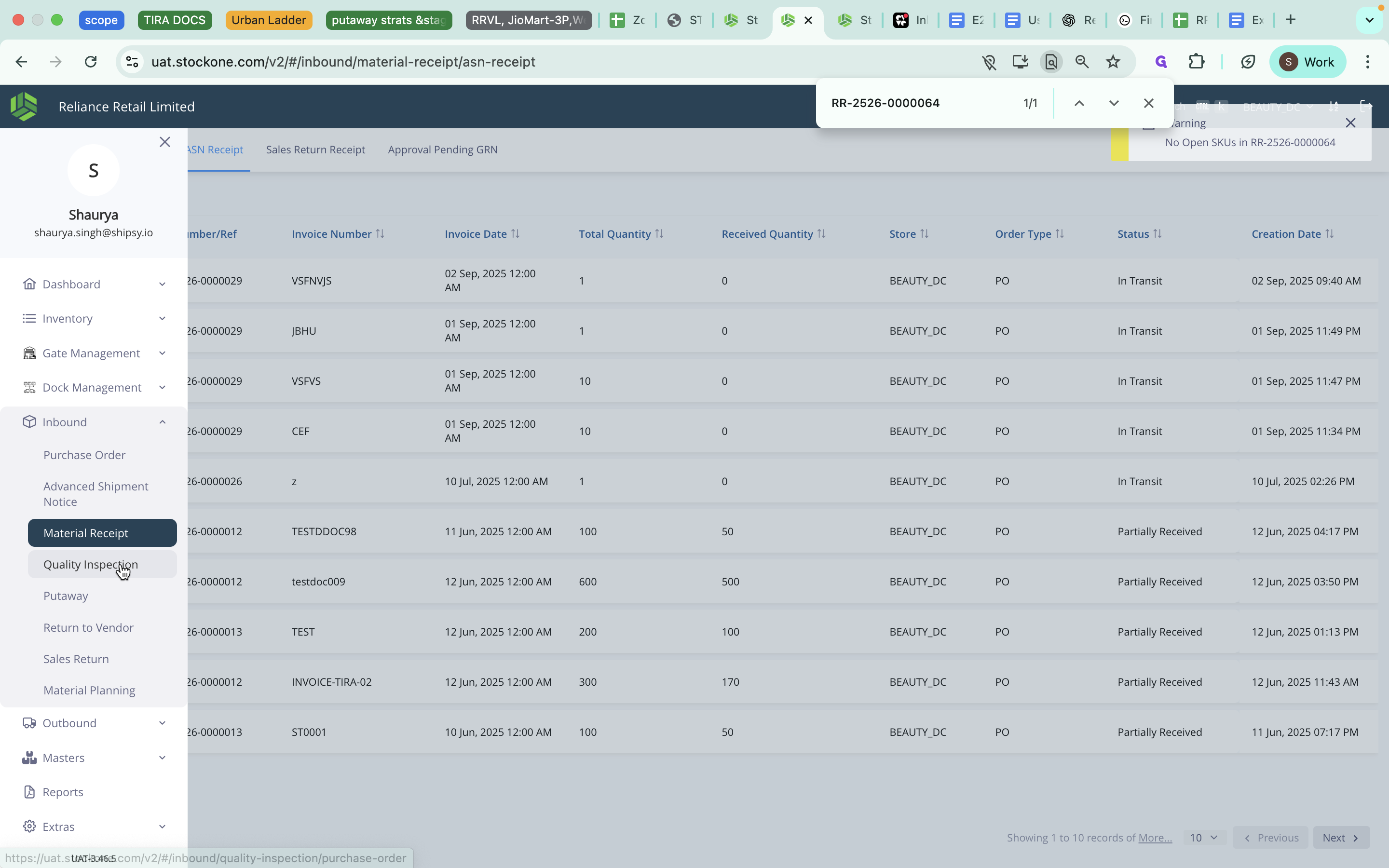

Go to Material Receipt and complete the GRN online.

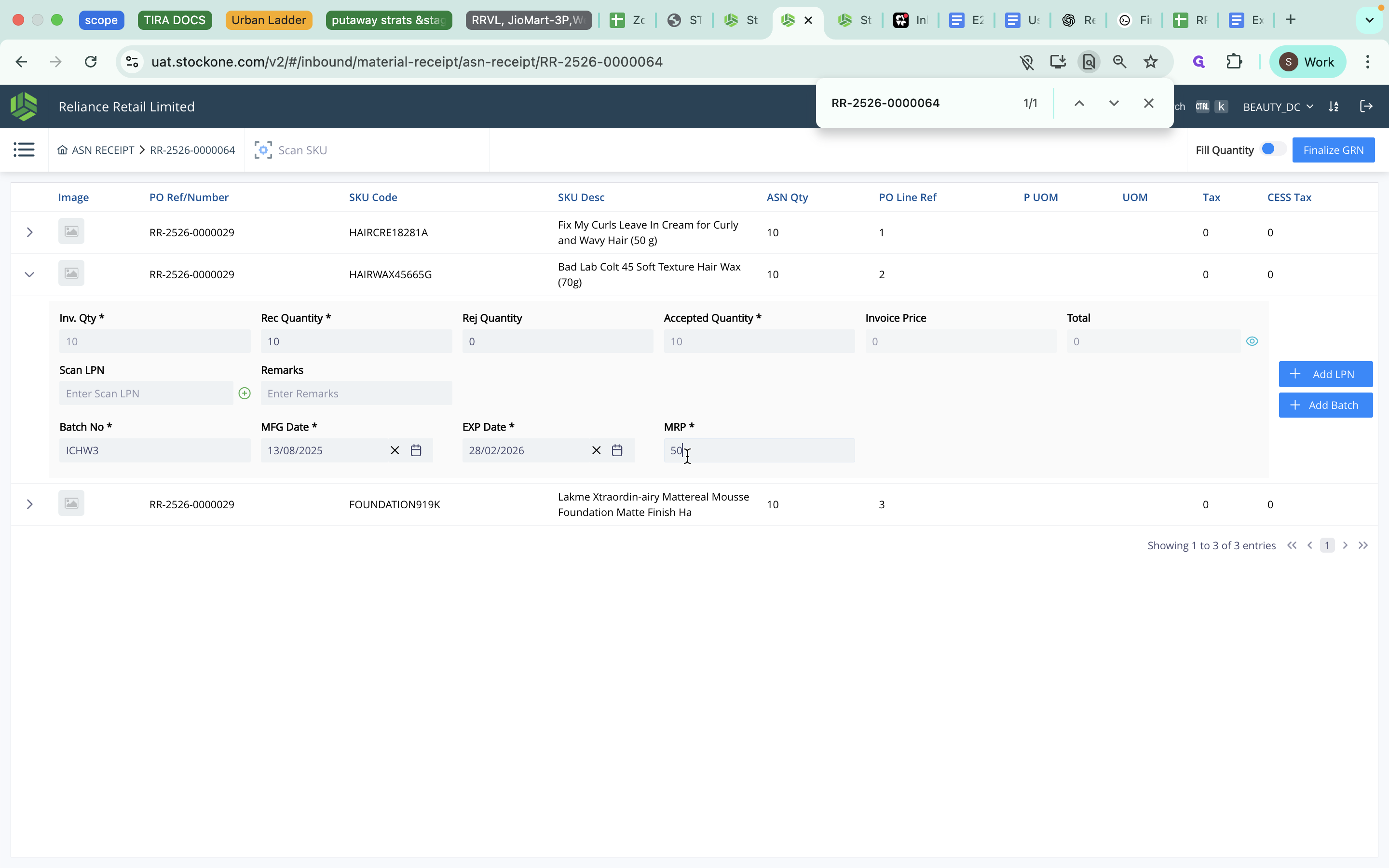

The batch details are already pre-filled. To test if the remaining shelf life falls below the minimum required, we can simulate this by reducing the expiry date here.

The shelf life of this SKU is 365 days, The shelf life of this product is 200 days. Customer shelf life is 150 days. The minimum shelf life is 100 days.

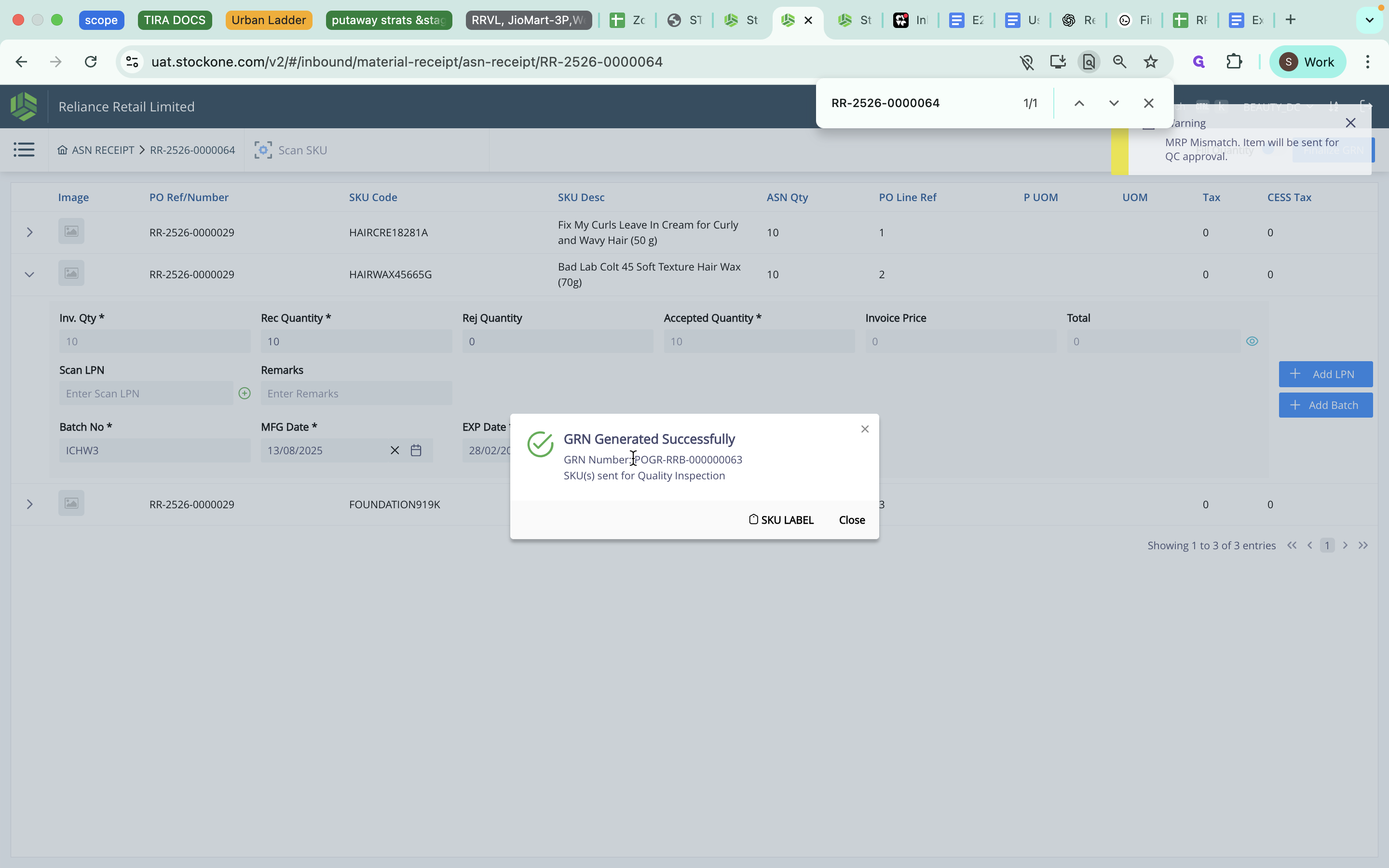

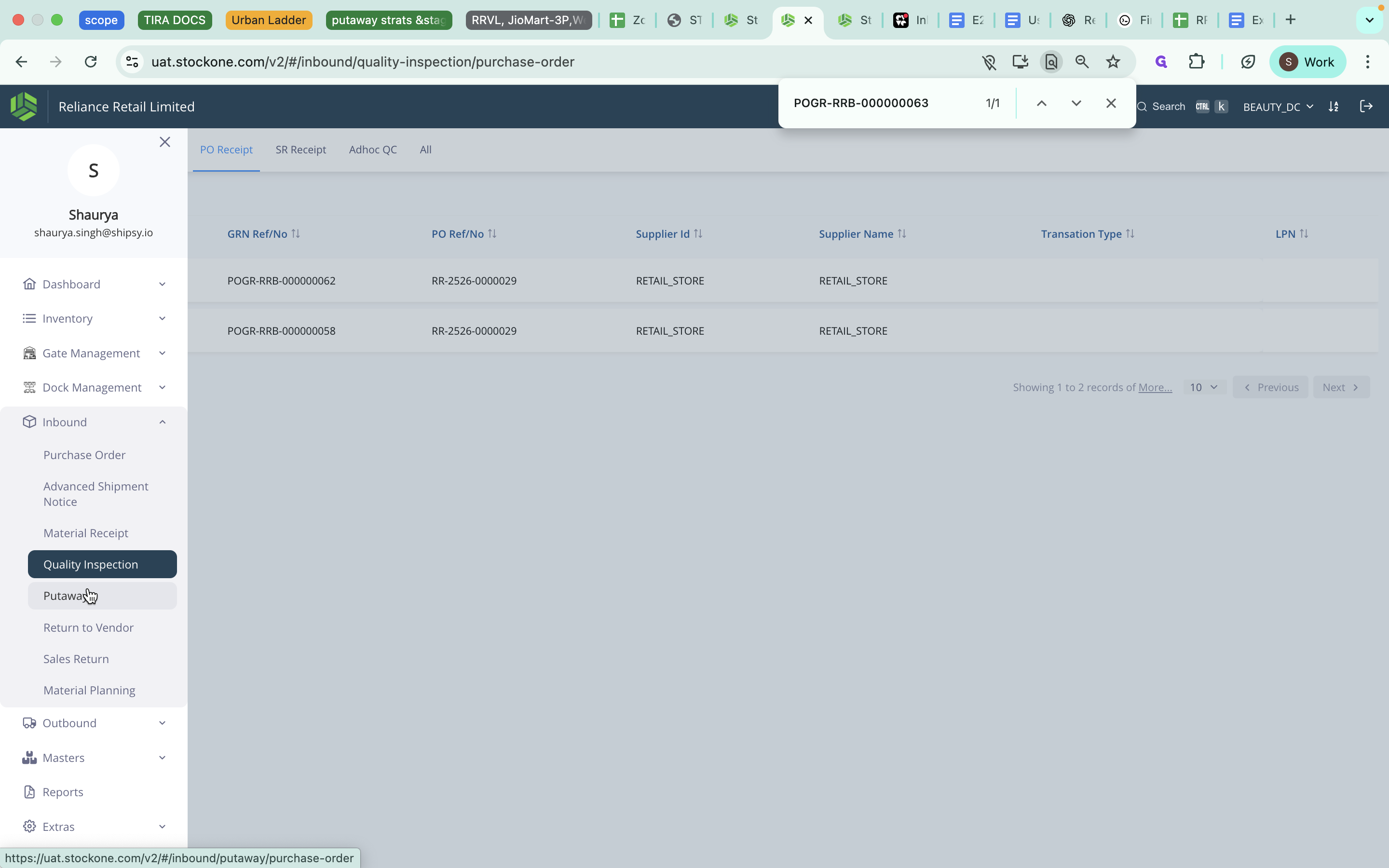

"Once the GRN is completed, the item is routed to QC if it fails shelf life or MRP validation."

Here, we can approve certain quantities and pack the rejected quantities into a separate LPN at the same time.

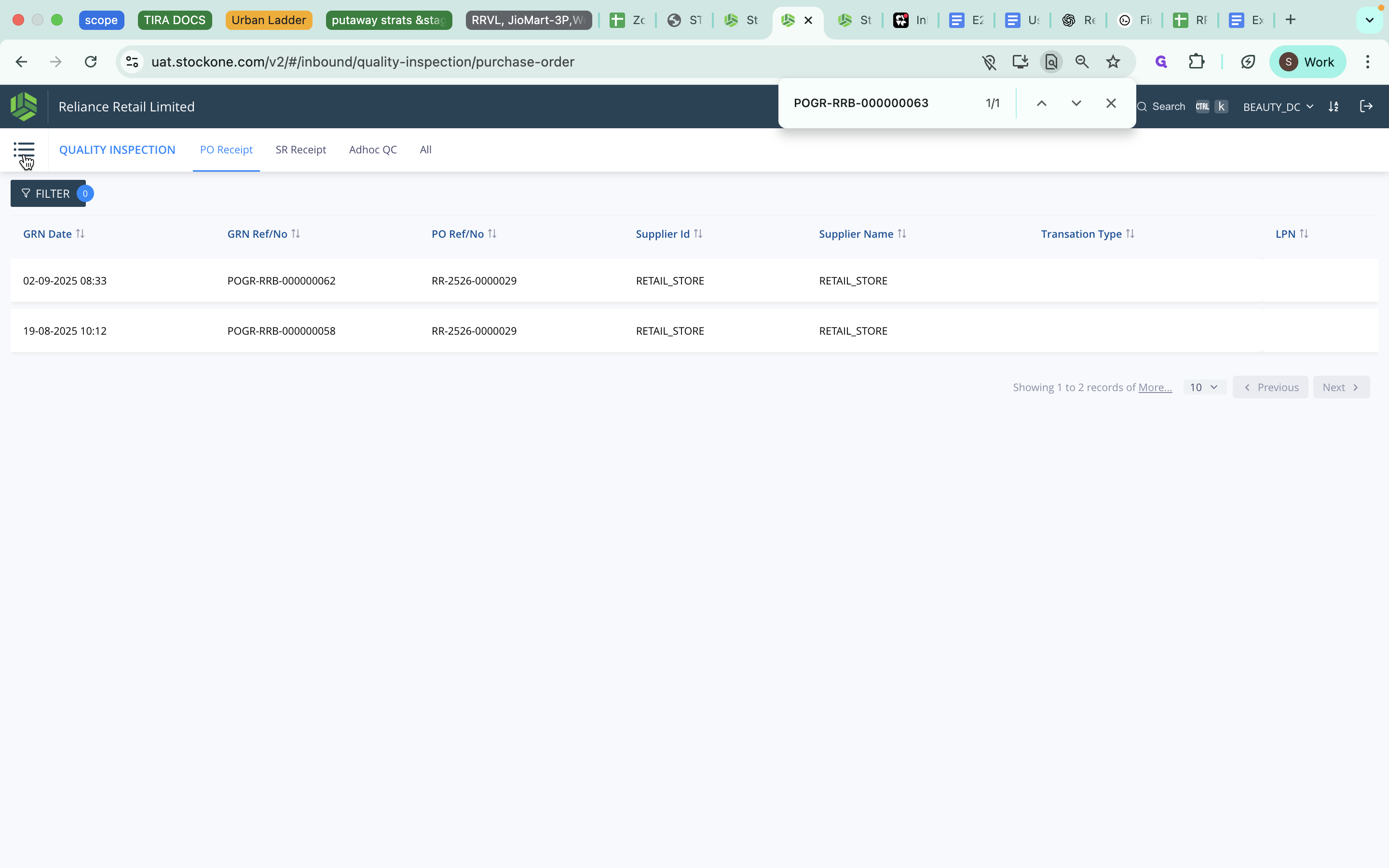

After the quality inspection is complete, items will automatically move from the inspection staging location (INSP) to the put staging location.

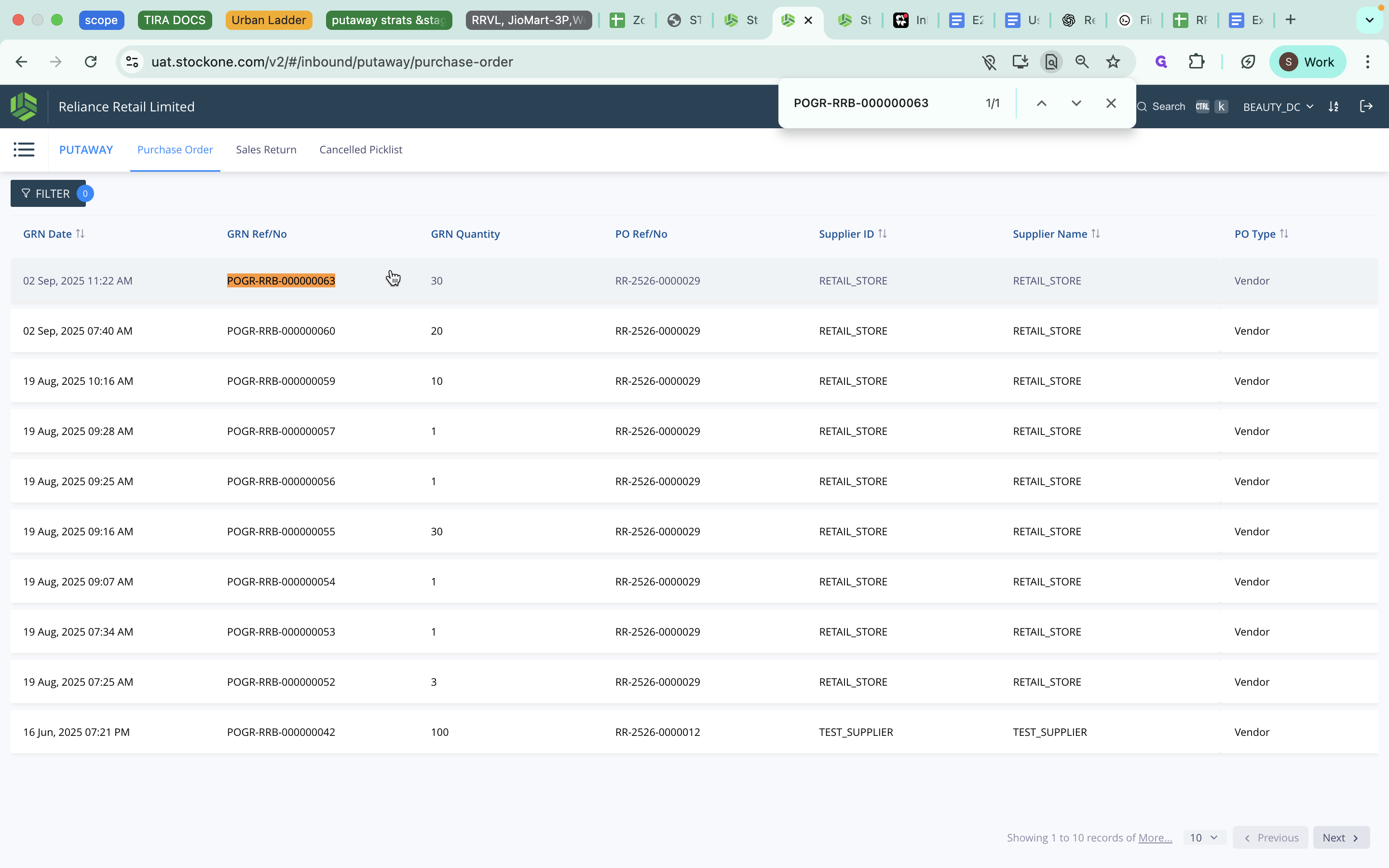

The GRN must be available for put-away.

Here, the quantities rejected during quality inspection are routed to a near-expiry zone. The accepted quantities are routed based on their SKU categories and assigned put zones.

We can continue to complete the put-away for this.

The put-away is completed.