Understanding the Part Availability Finkelstein Screen for Inventory Management

Learn how to navigate the Part Availability Finkelstein screen to manage inventory levels, view stock availability, and handle customer orders efficiently.

In this guide, we'll learn how to navigate the Part Availability Finkelstein screen. This tool helps us track inventory levels and availability on specific dates, considering purchase orders and incoming goods against open customer orders. We'll explore how this screen supports various stages, from quoting to order entry, and how it helps us understand inventory status. Additionally, we'll demonstrate how to use this screen for customer quotes and manage alerts when orders might lead to negative inventory.

Let's get started

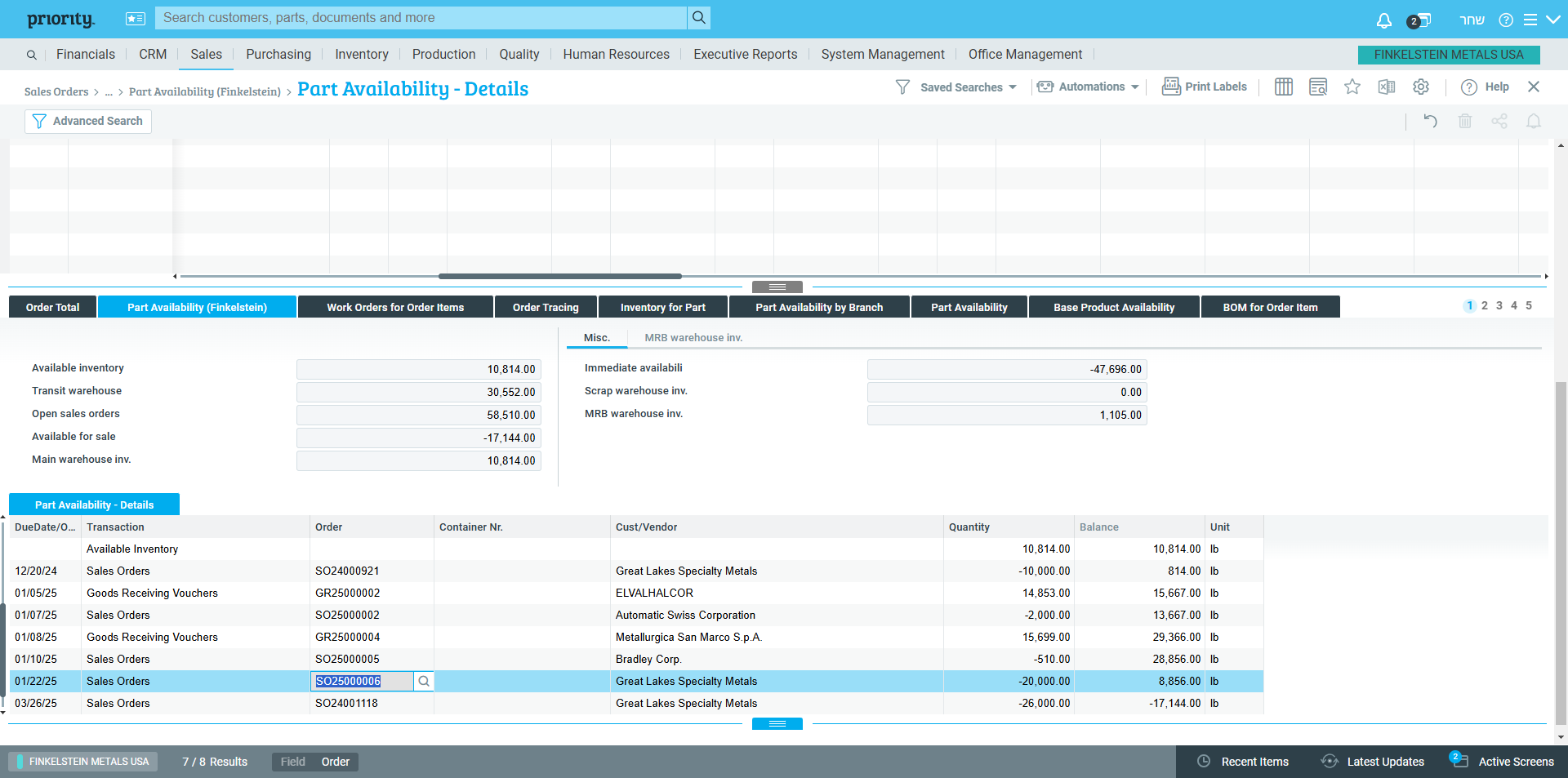

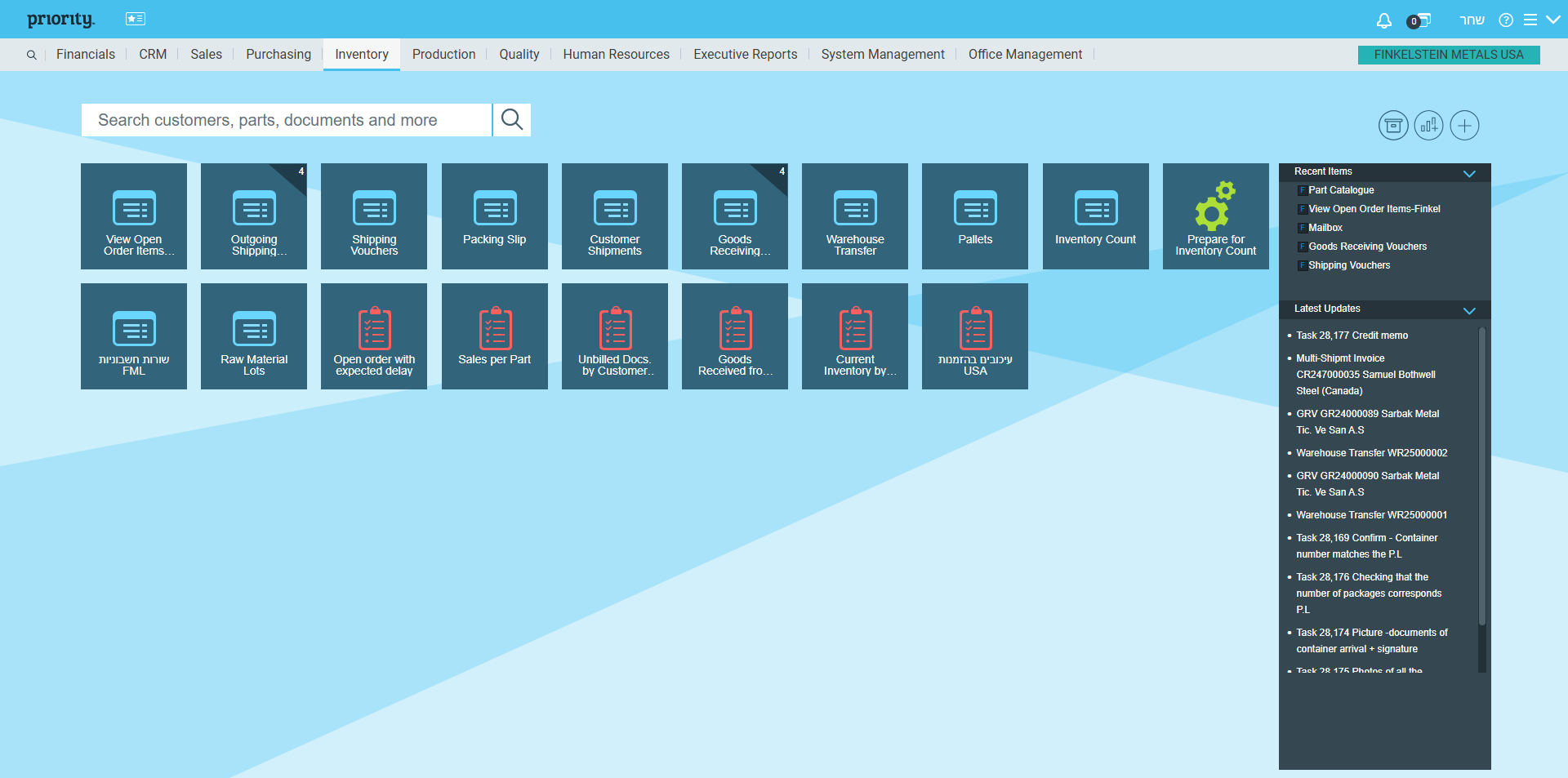

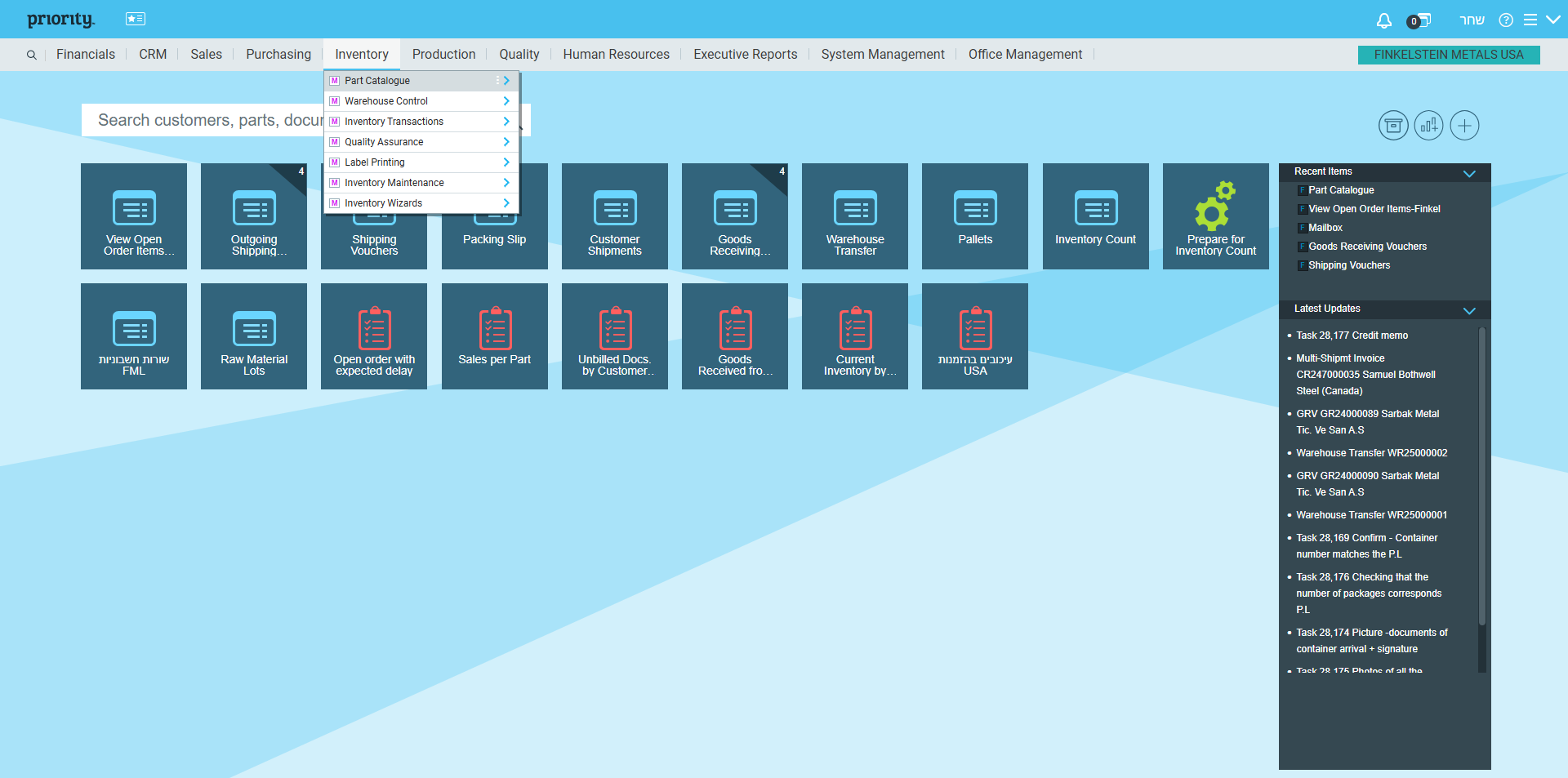

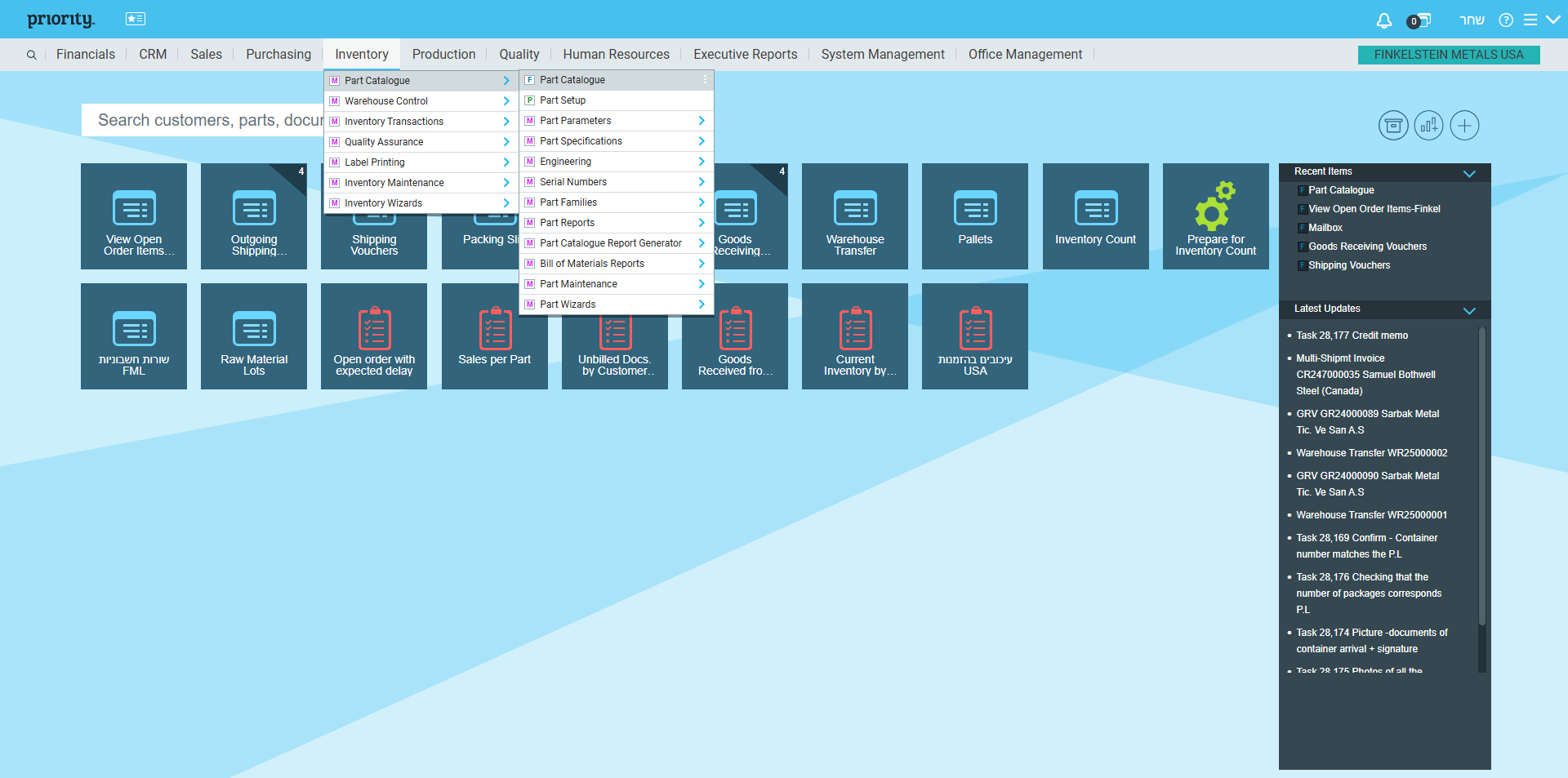

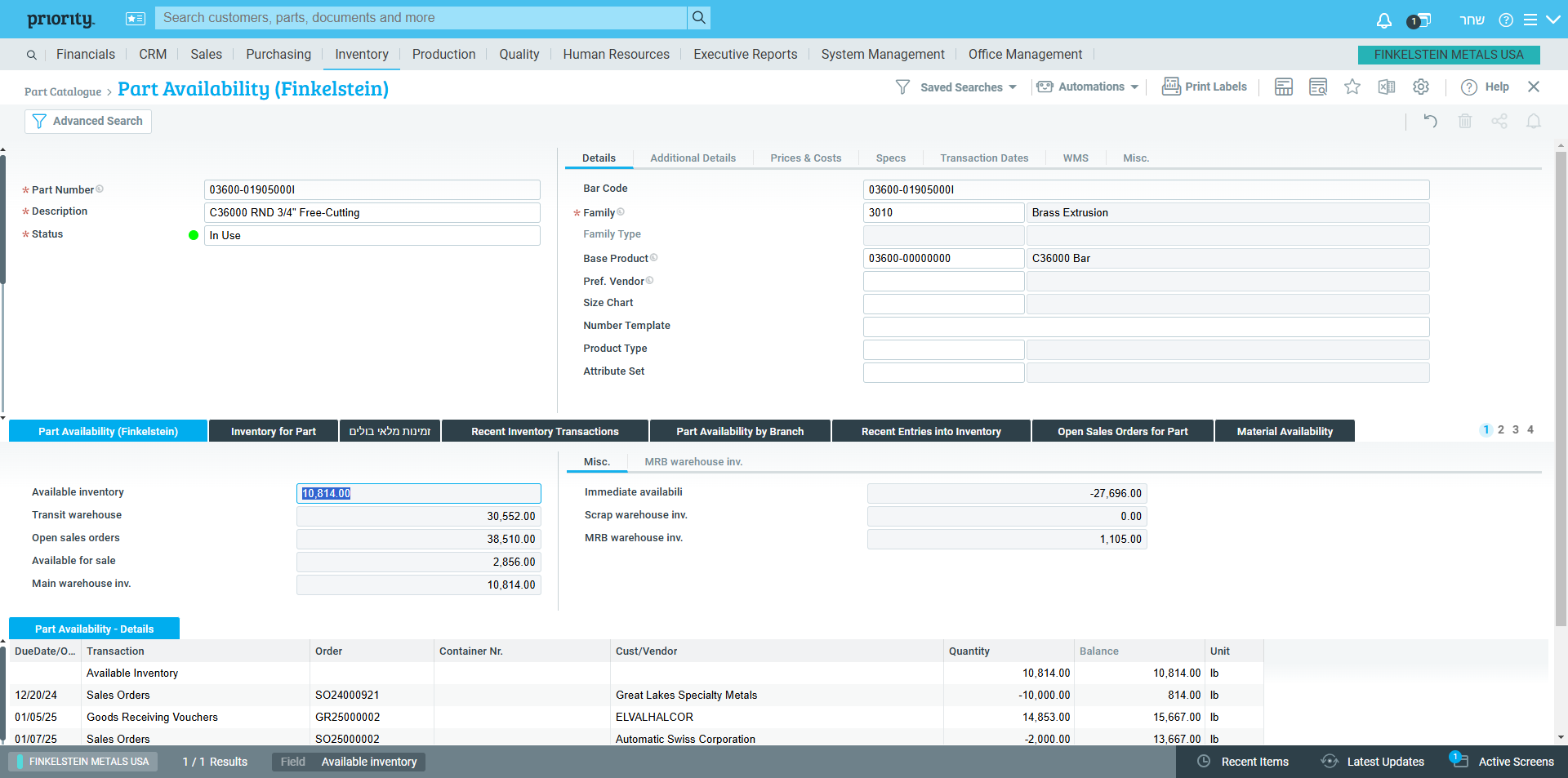

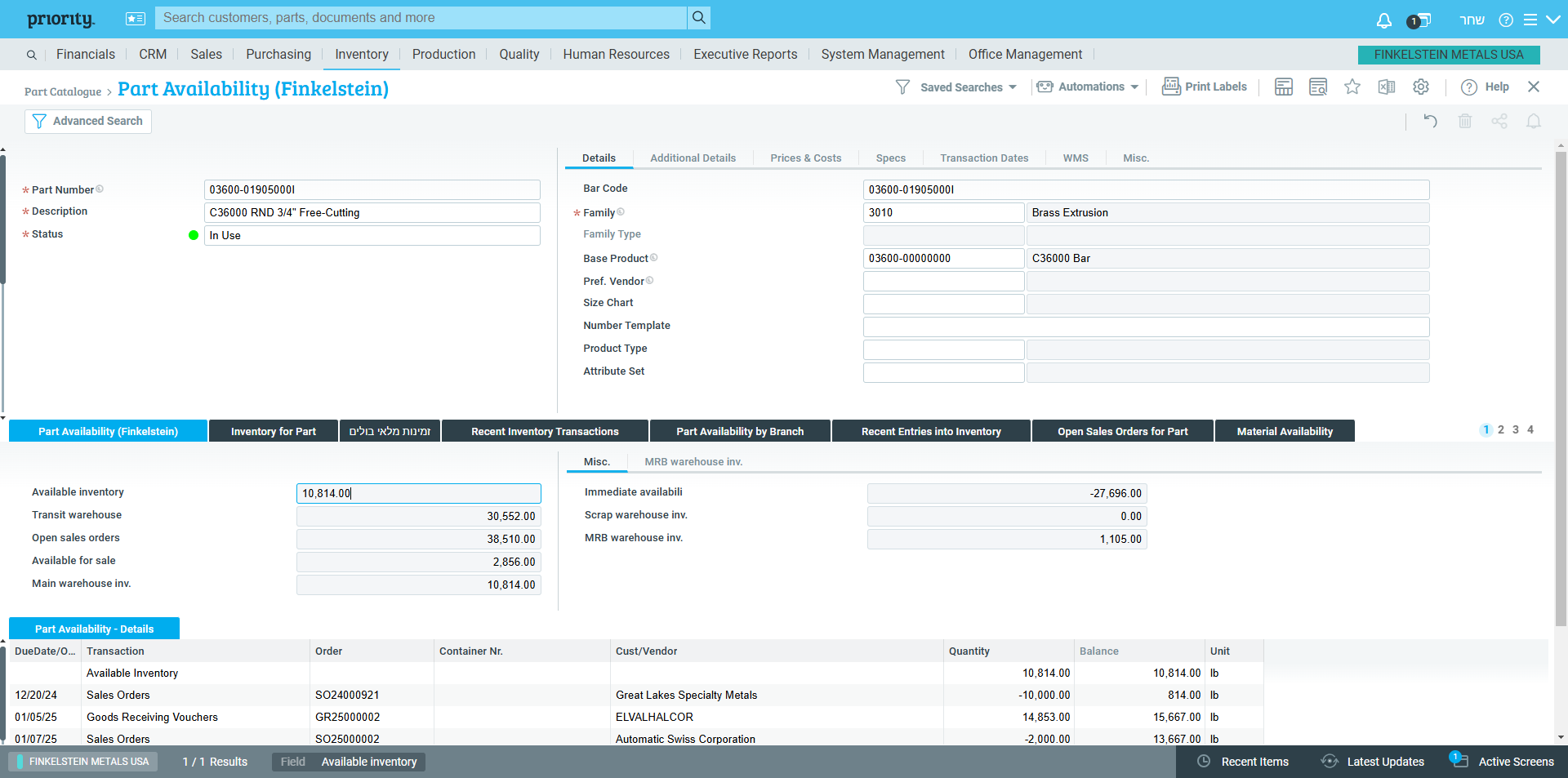

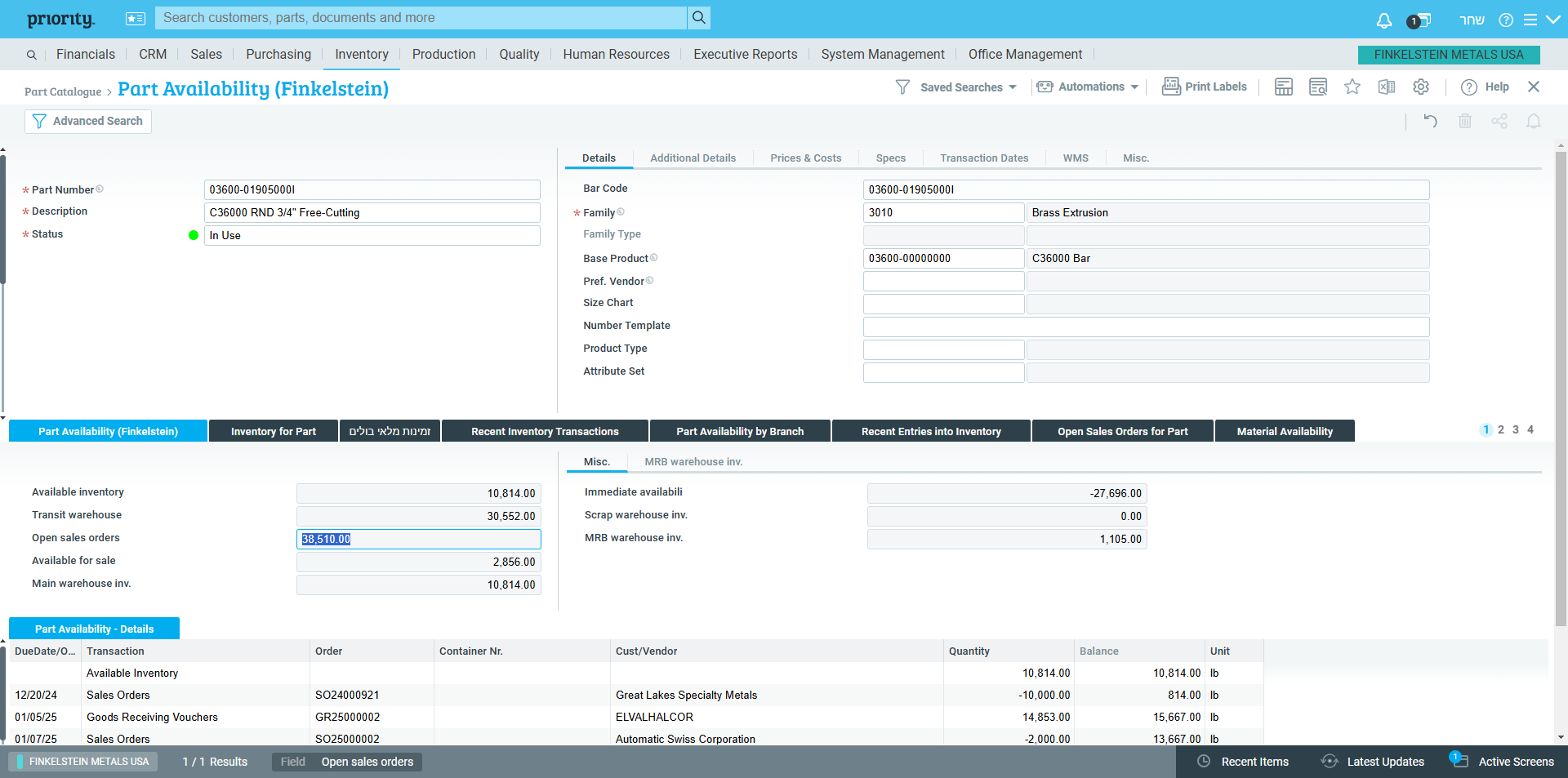

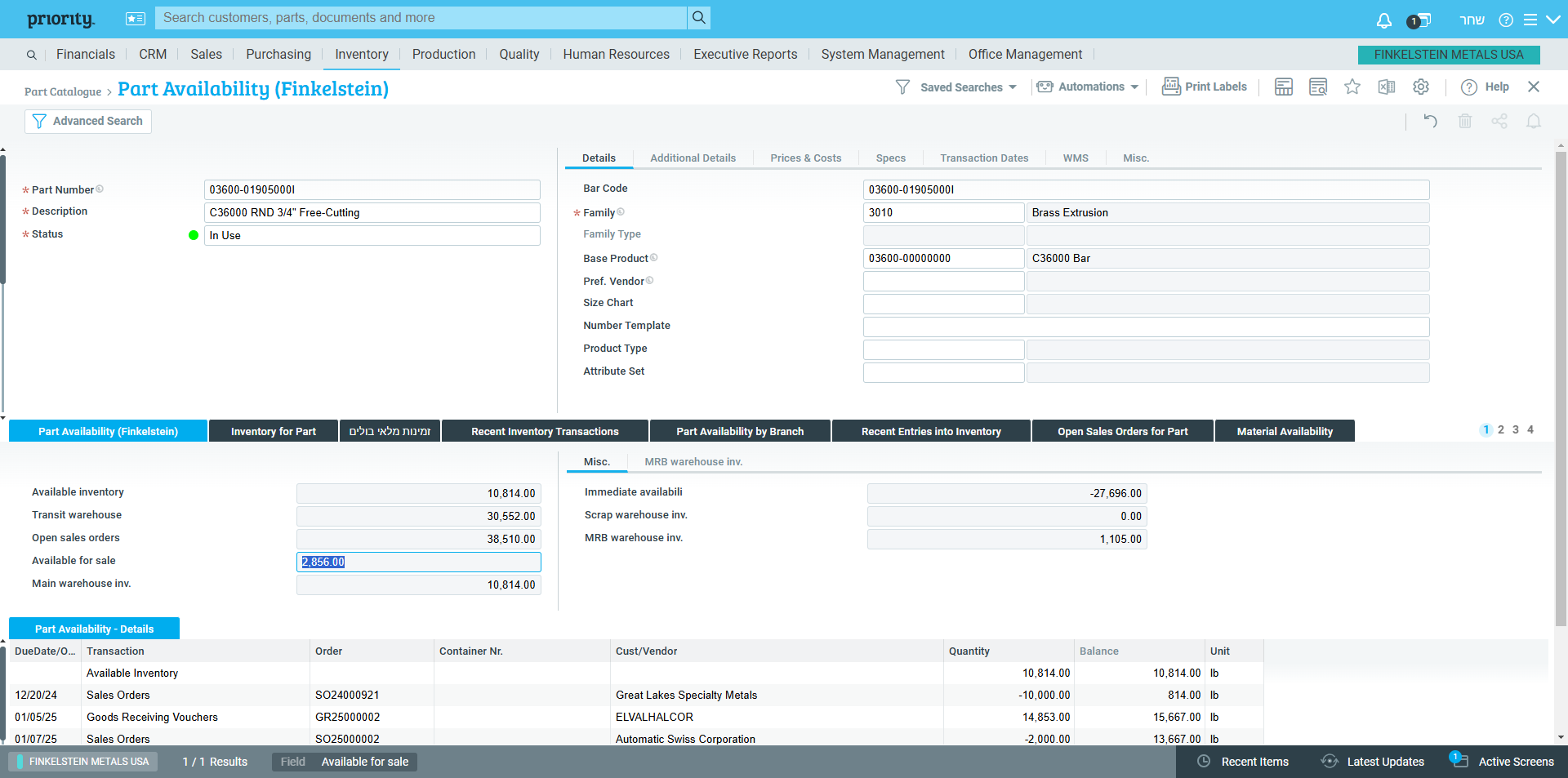

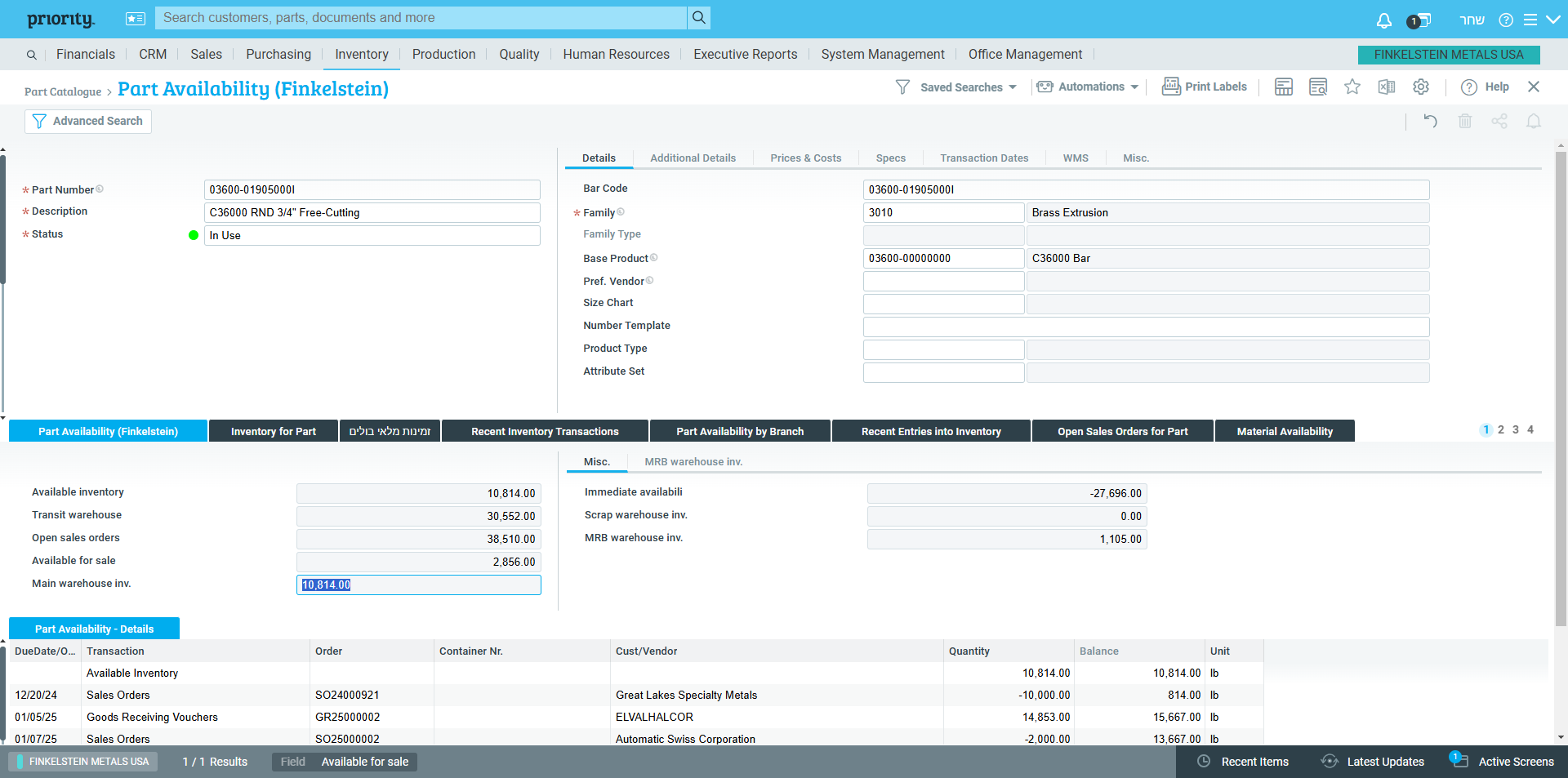

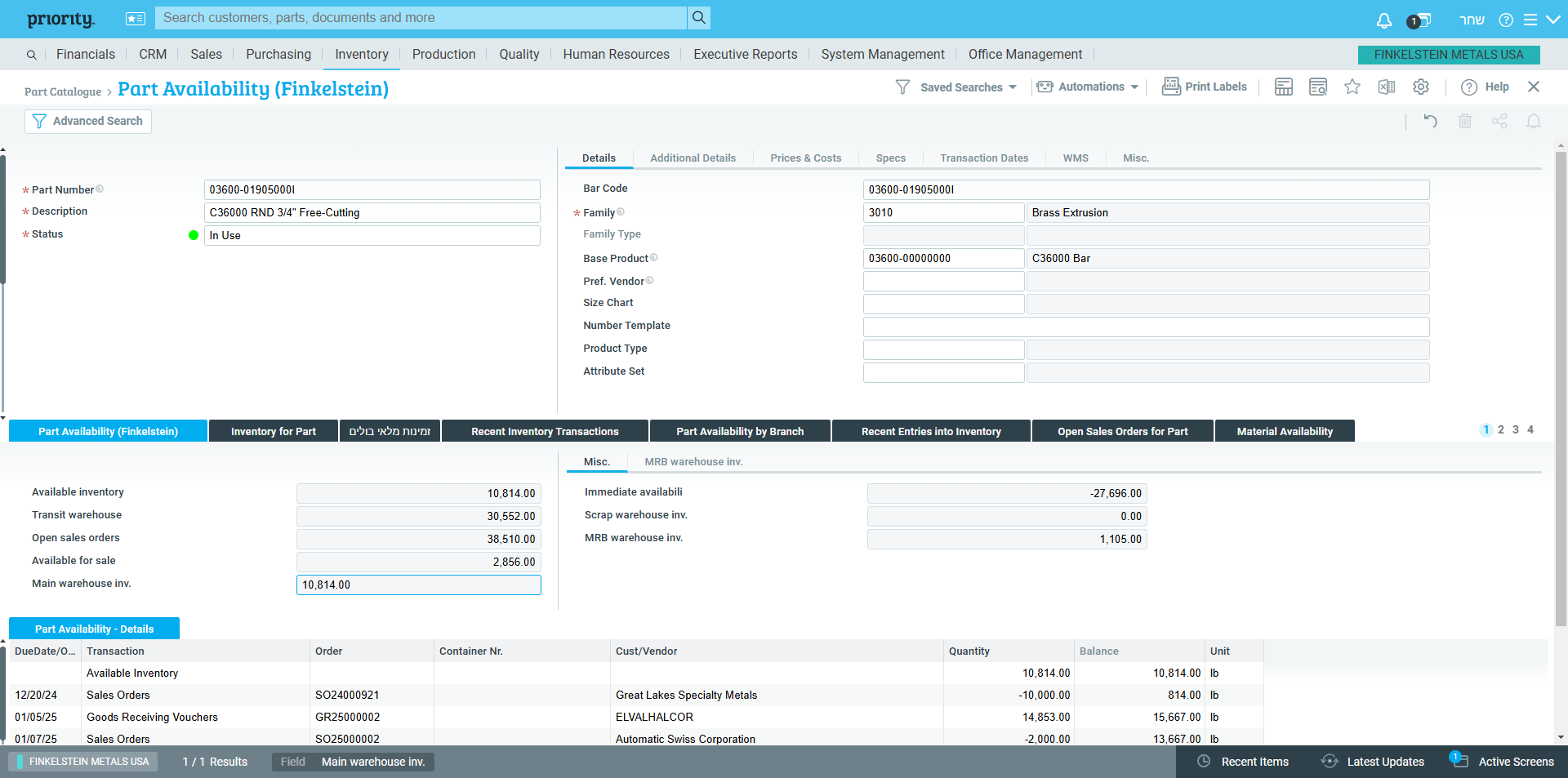

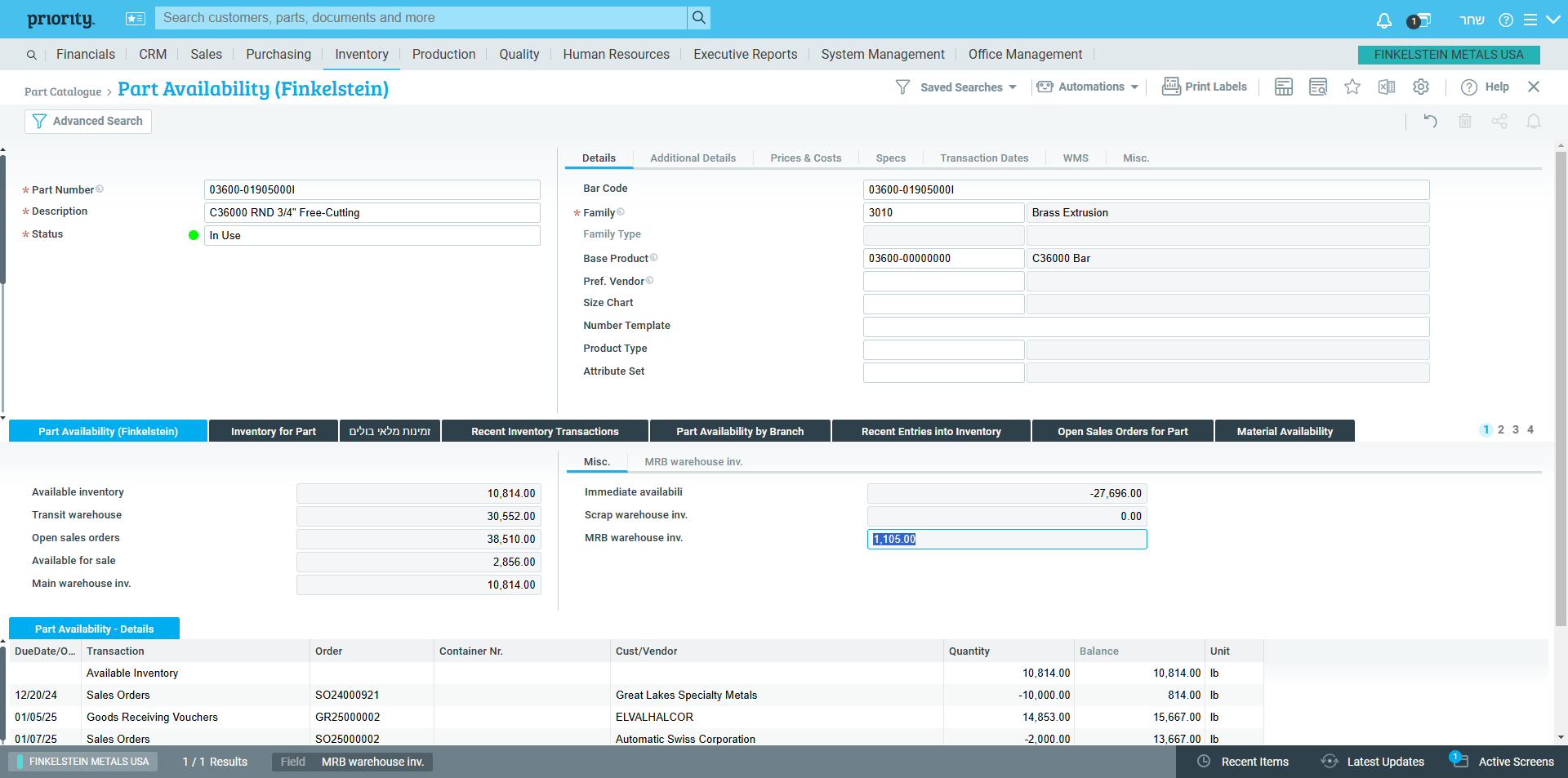

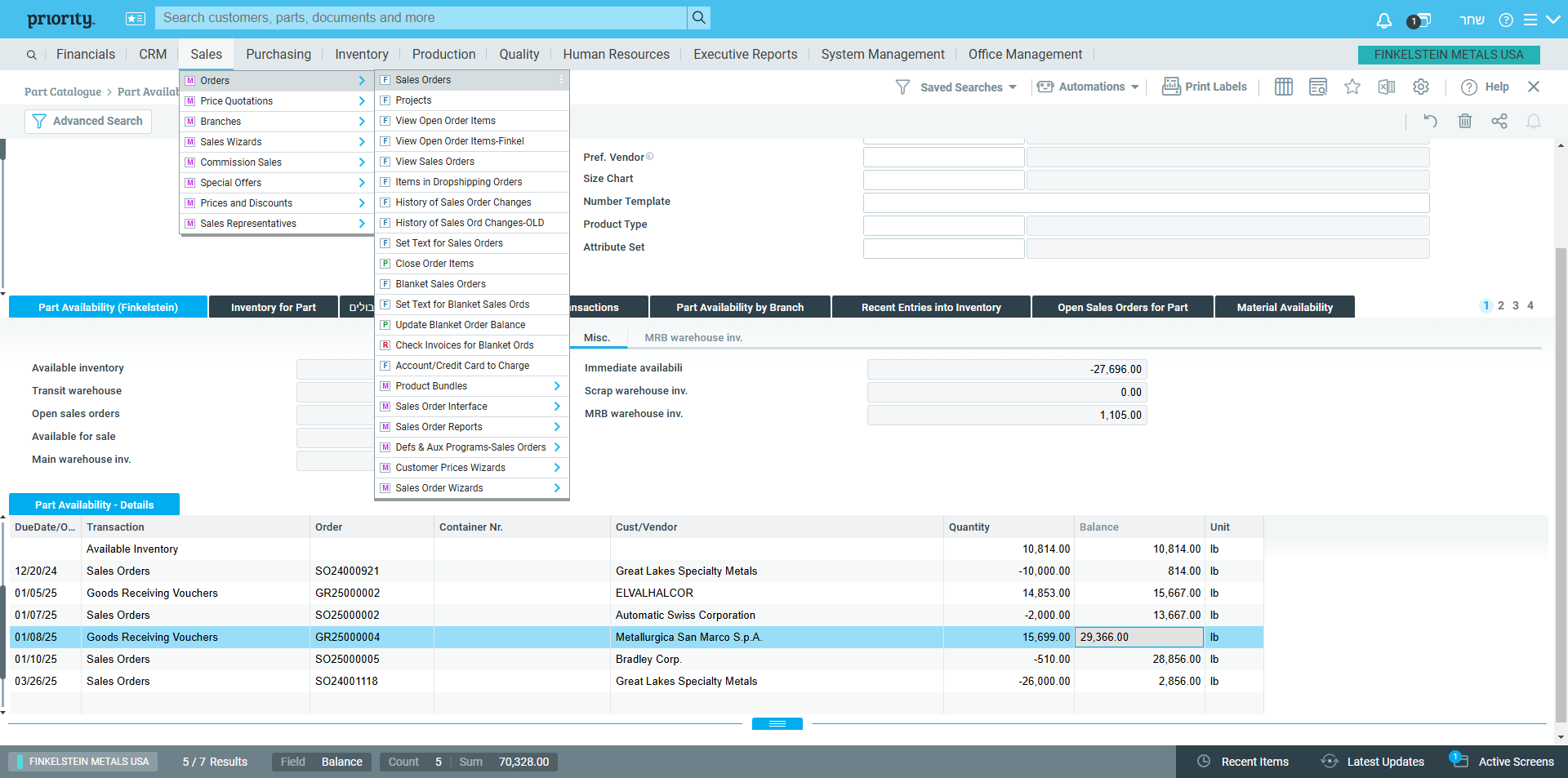

Hello everyone. In this guide, we will explain the Part Availability Finkelstein screen. This screen allows us to view our inventory levels and availability on any given date, based on purchase orders and incoming goods, compared to open customer orders we need to ship. First, we will access the screen. The Part Availability Finkelstein screen is integrated into several other screens to help us understand inventory during the quotation stage, when entering order lines, and when we simply want to check stock levels. To demonstrate the screen.

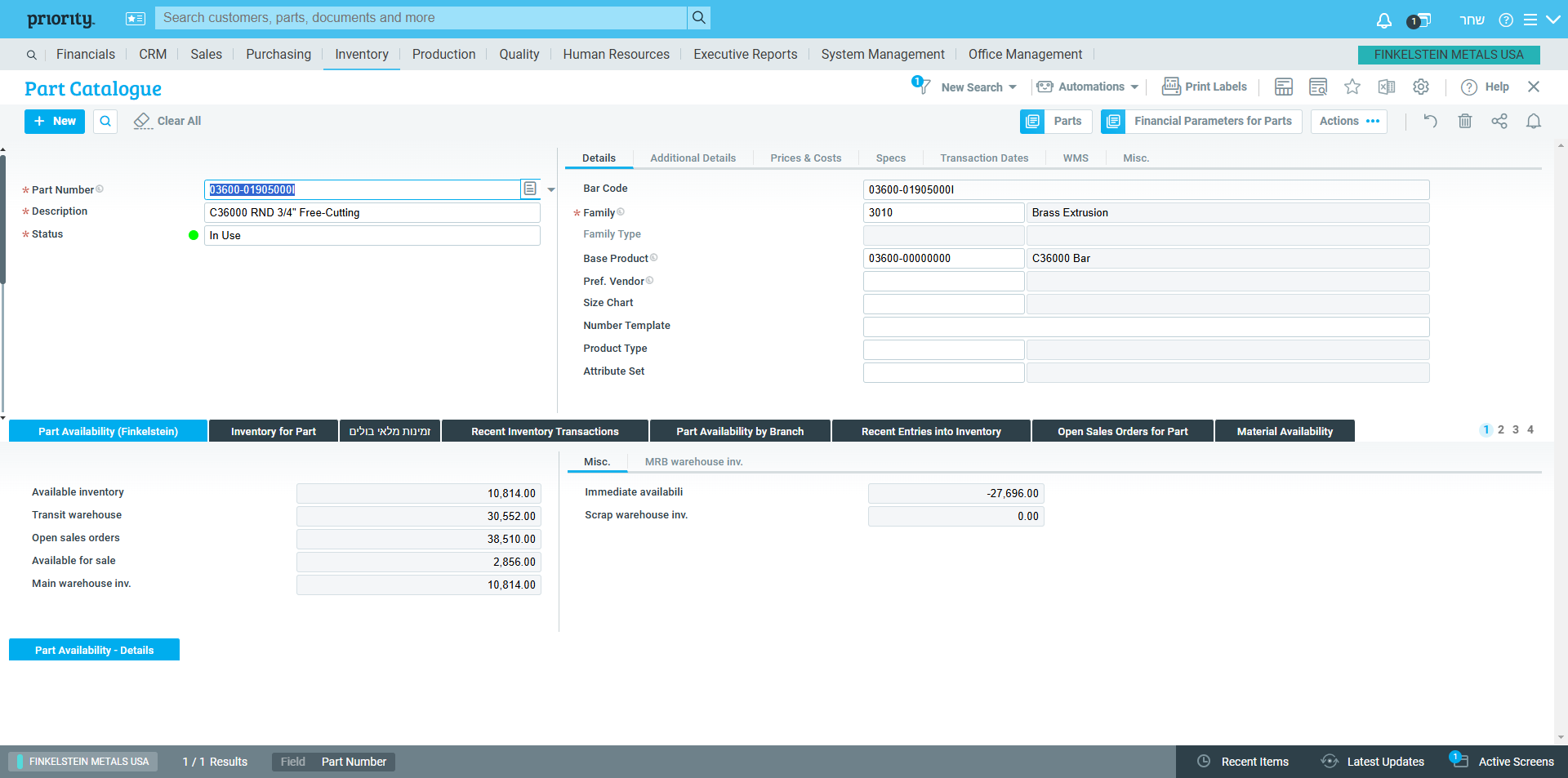

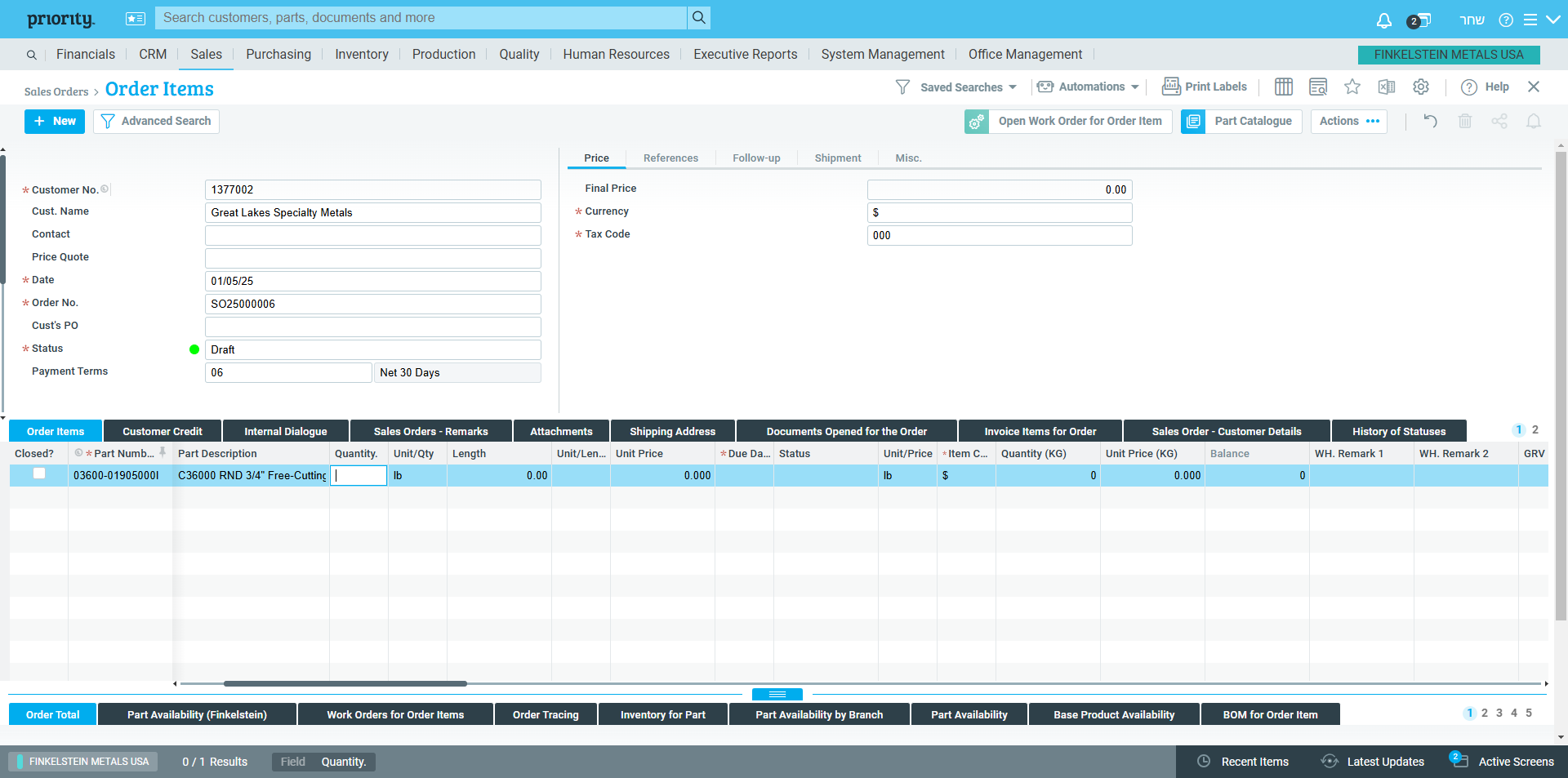

We will now enter the 360 diameter three-quarter and check its stock availability.

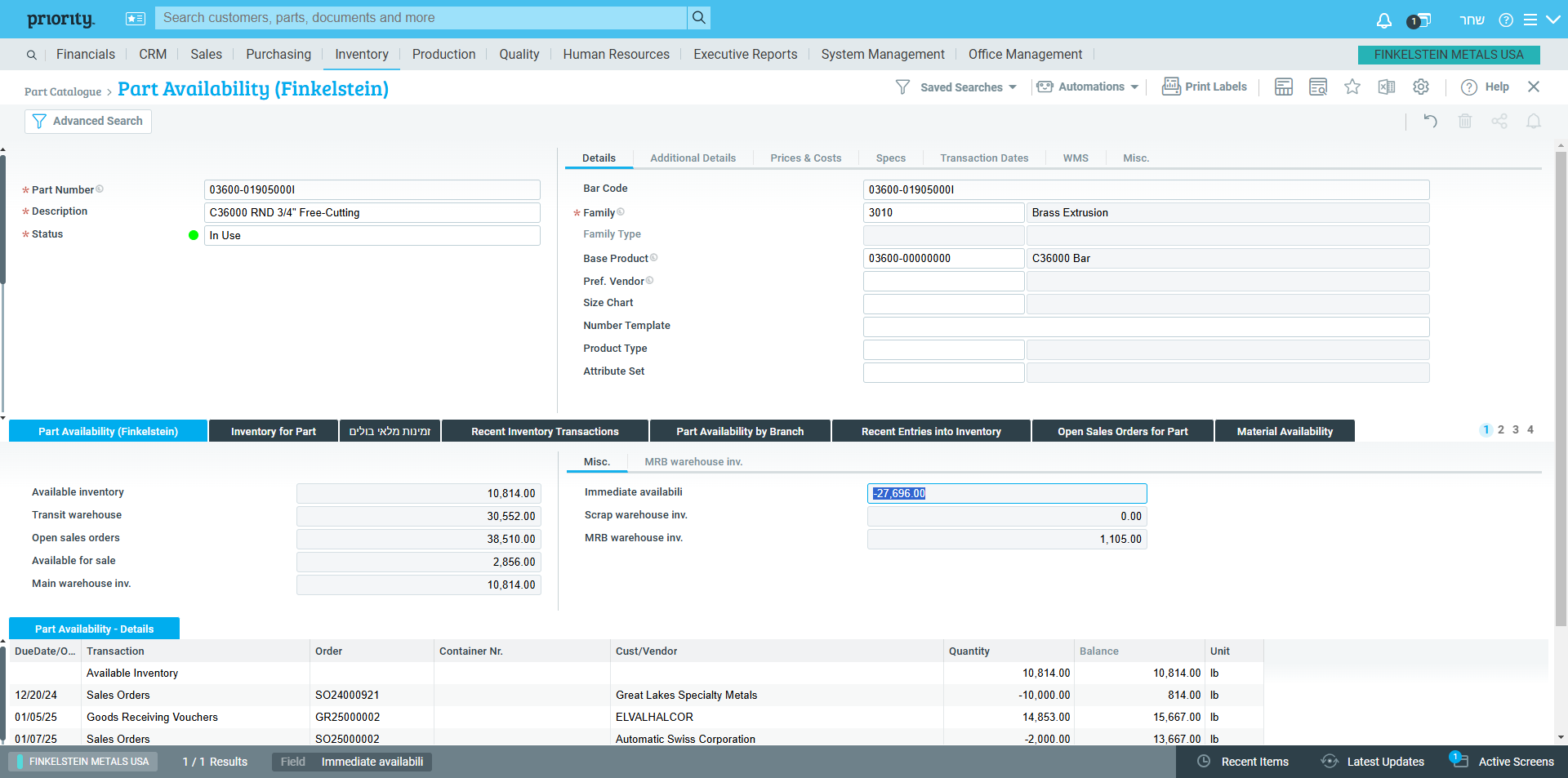

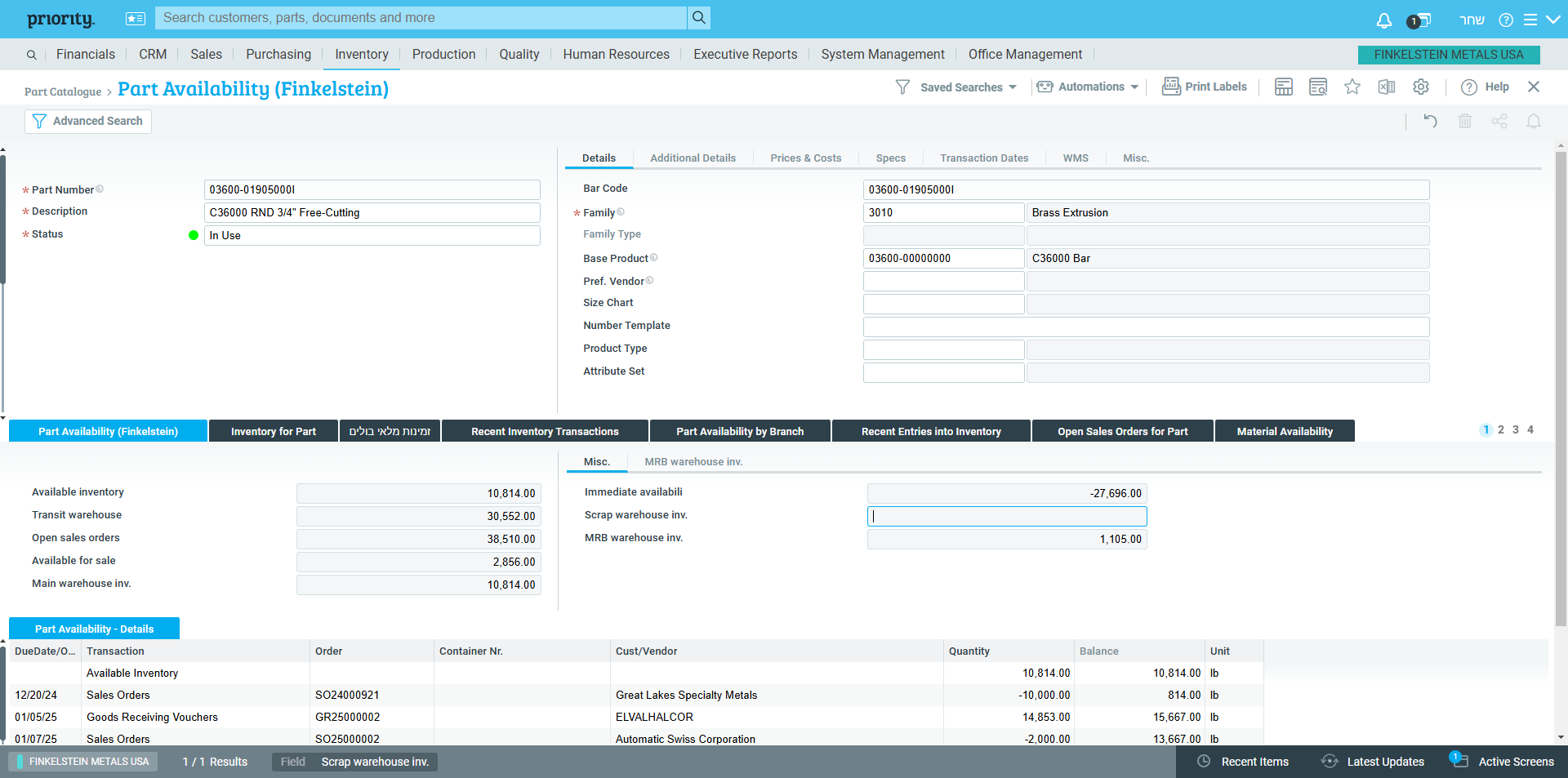

First, we'll explain all the fields available on this screen.

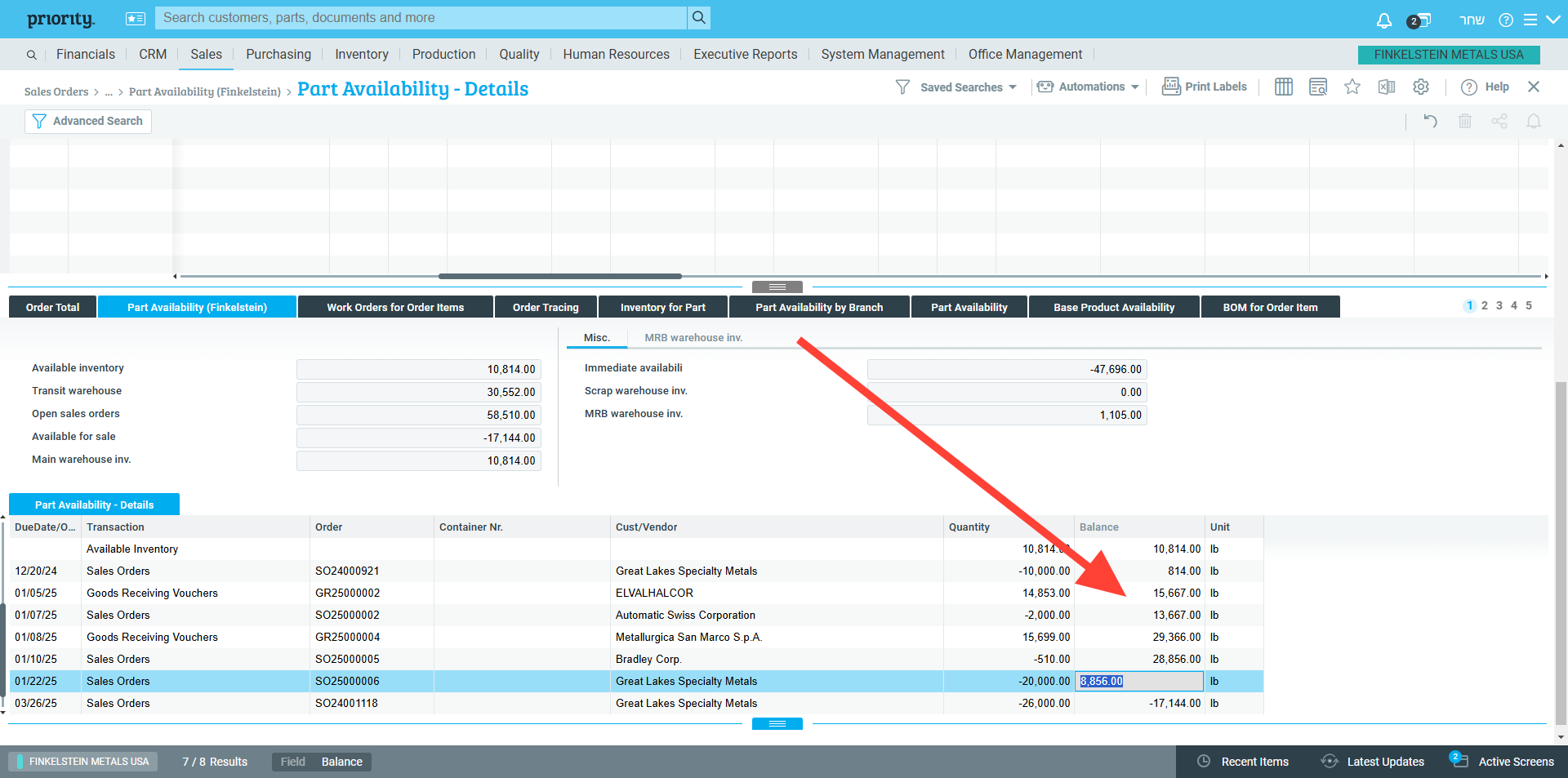

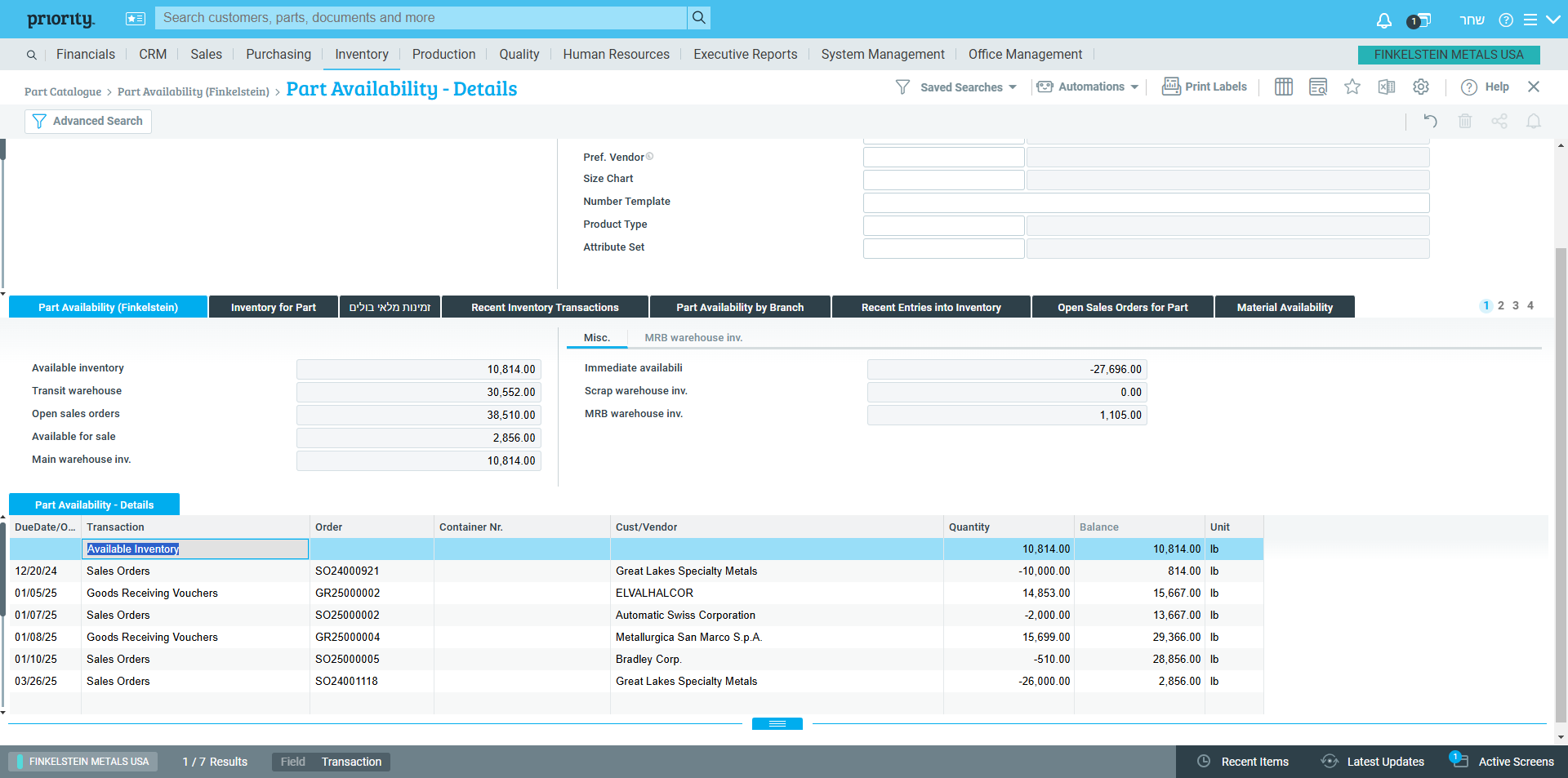

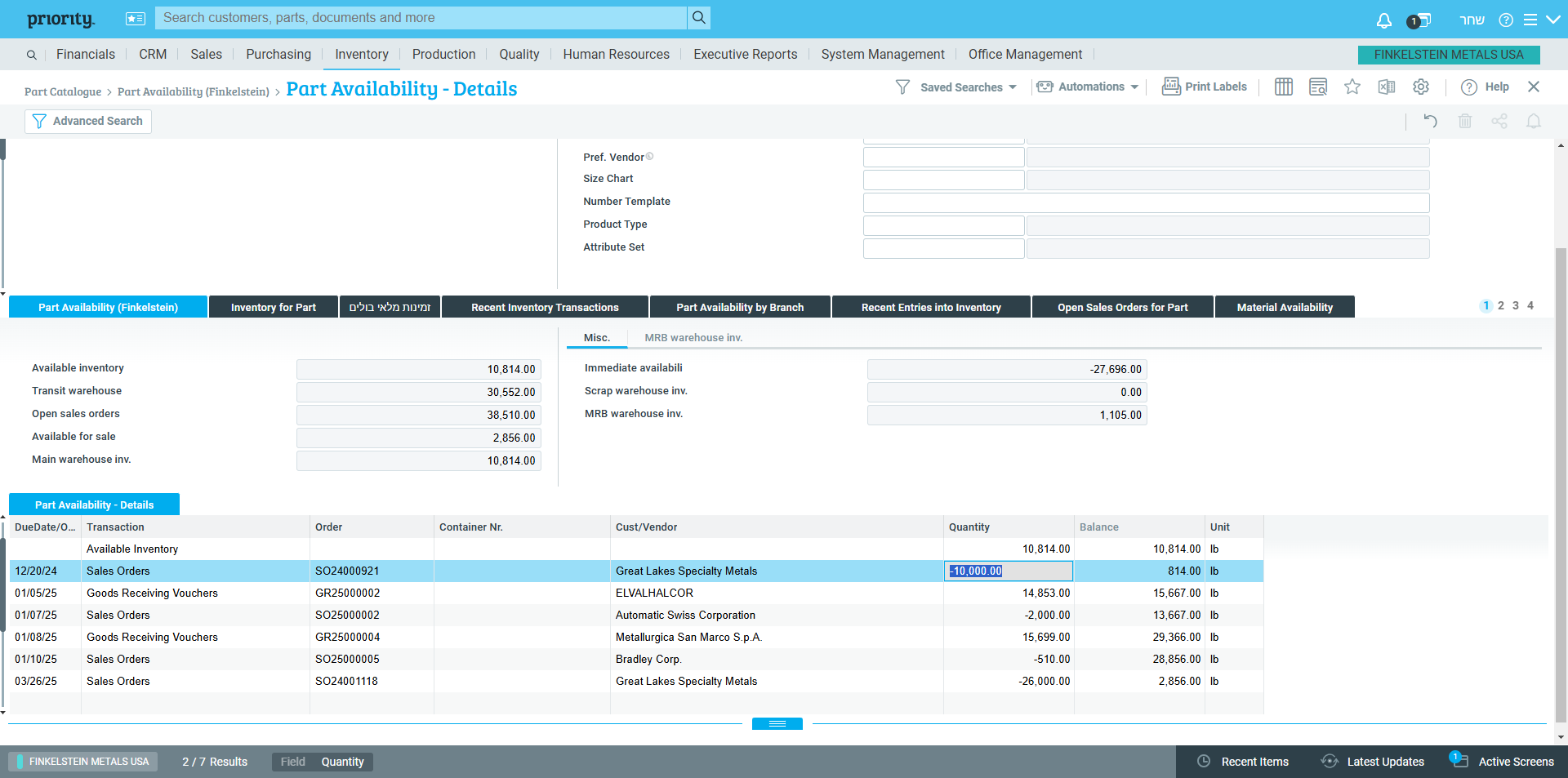

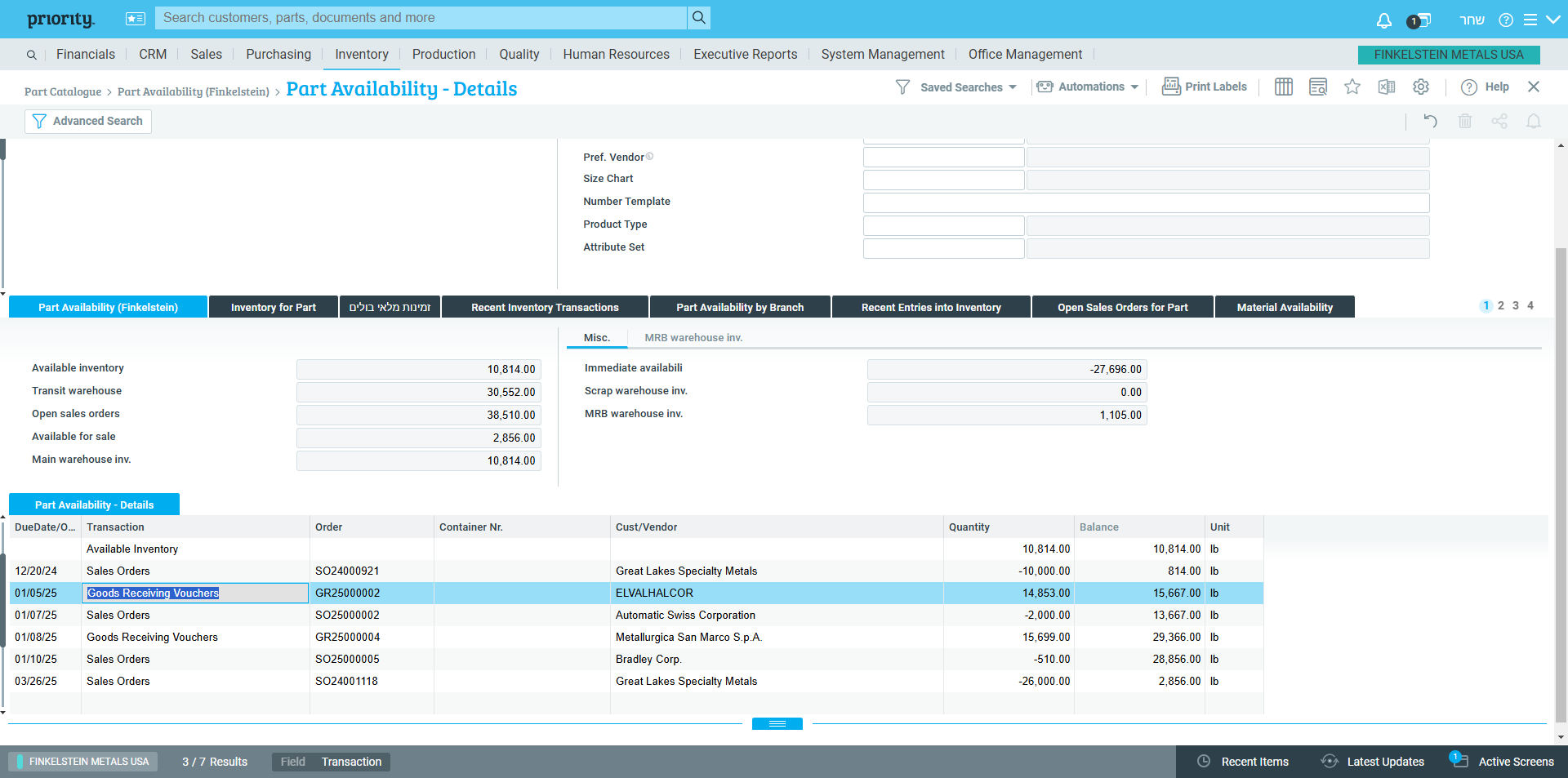

The next screen, Part Availability Details, provides detailed availability for each relevant date in the system.

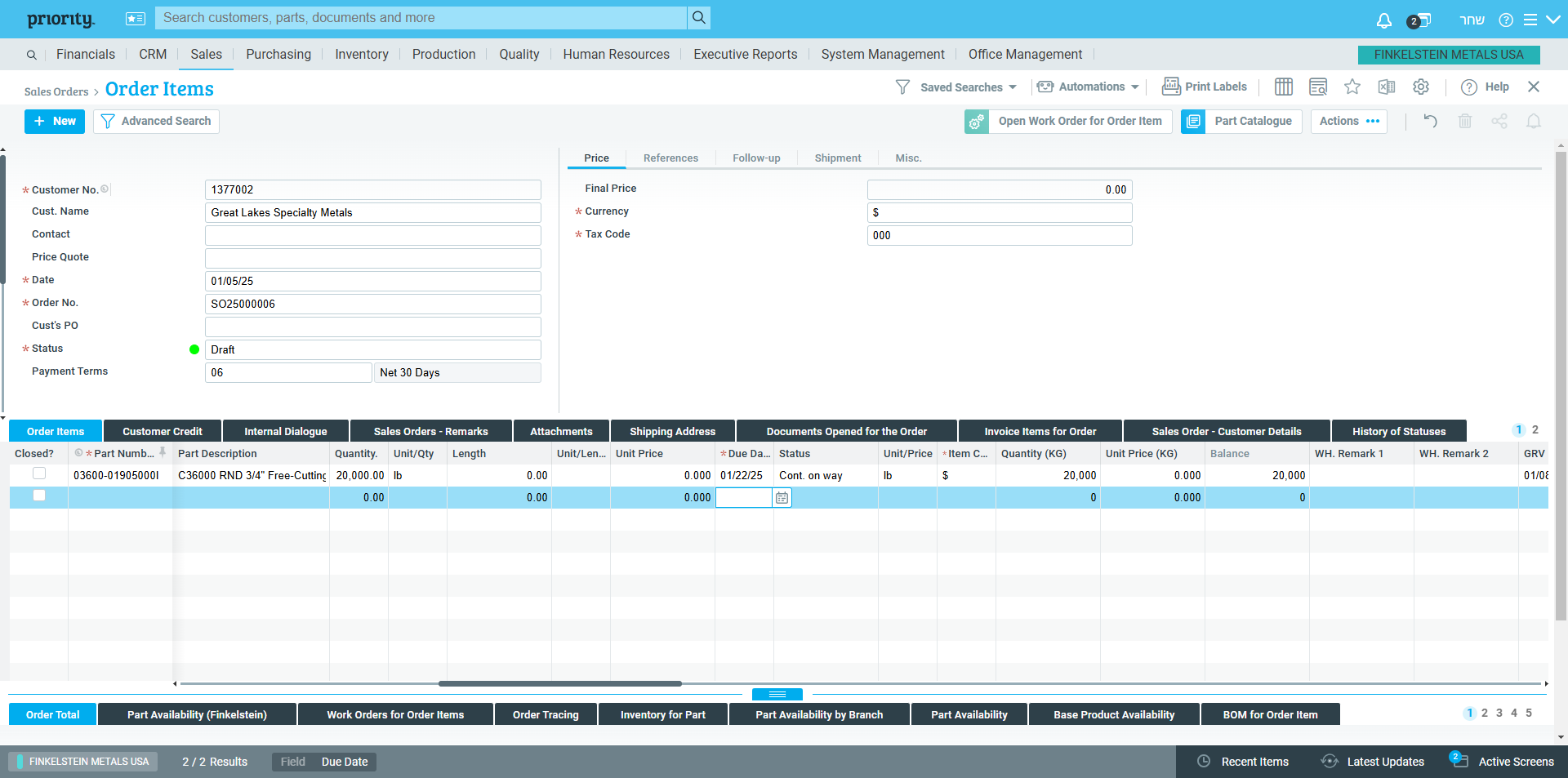

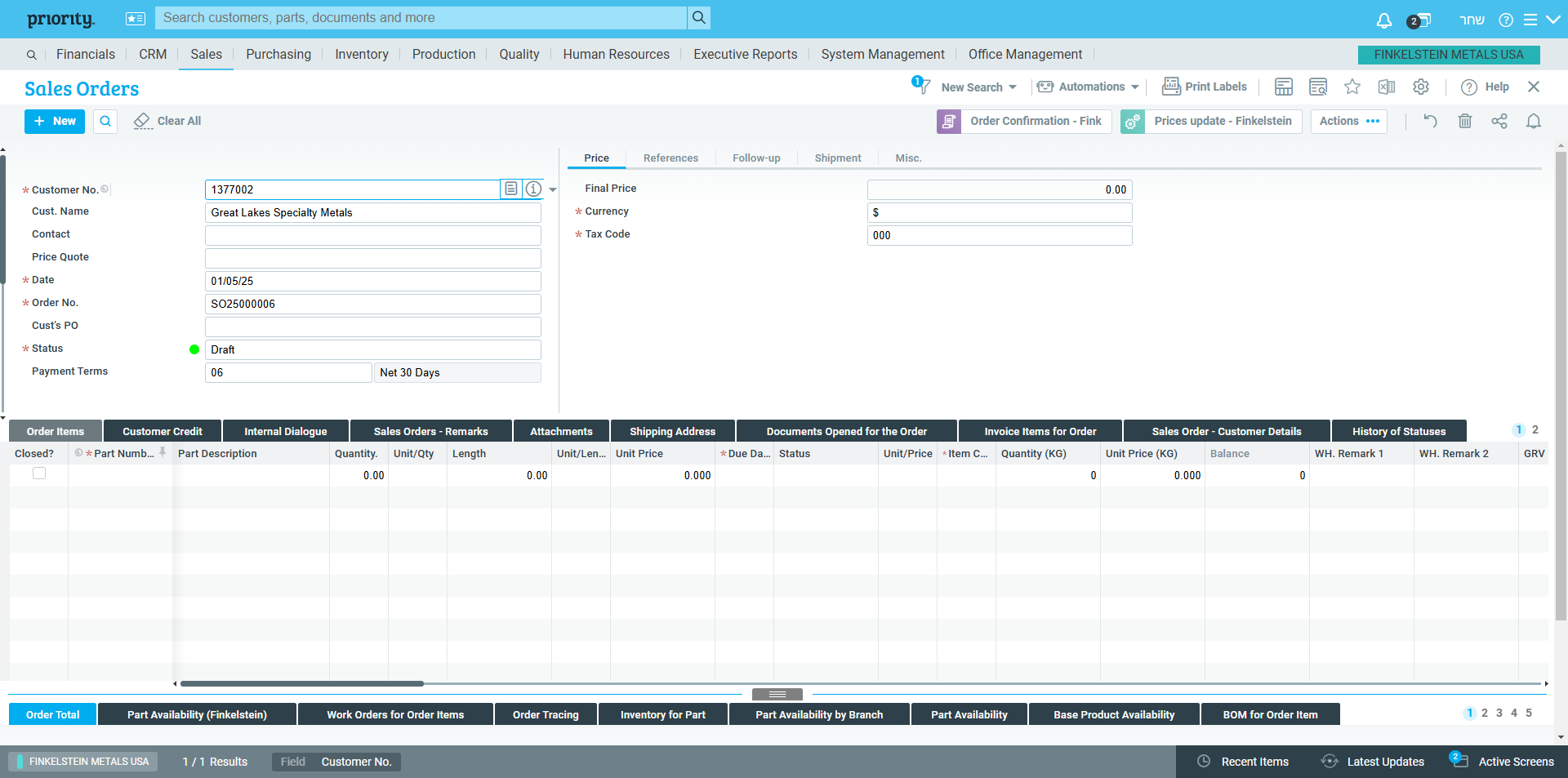

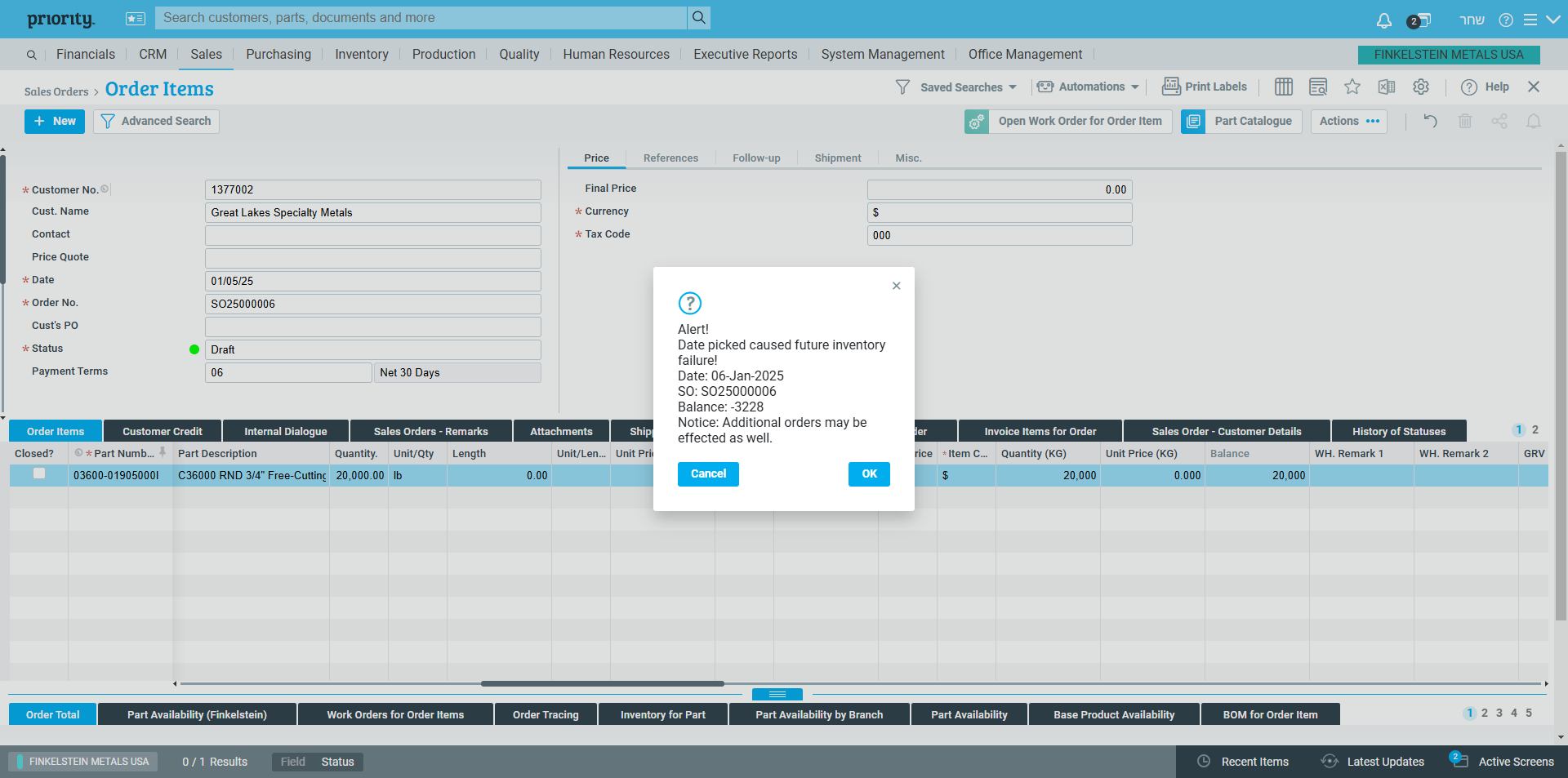

Next, we'll explain how we receive alerts when me making the customer order

The Status field on the right indicates that the material is currently in "Cont. on way". This suggests that the material will arrive before the delivery date set for the customer.

This field will perform the calculation and enter the status automatically in the order line after we have left the line